Technical Challenge

Finite element (FE) simulations play a crucial role in modern engineering design and analysis, enabling engineers to predict and optimize the mechanical response of designed parts prior to creating a prototype. There are three critical inputs to all FE simulations:

- geometry, defined by the design engineer;

- loading, dictated by the designed use of the part; and

- the material model.

The material model is often the most challenging portion, requiring accurate test data, an appropriate choice for the material model and FE package, and correctly calibrating the selected model to the test data. Commercial FE packages have limited material model choices for polymers, and selecting the most appropriate material model and correctly determining the material parameters can be challenging.

Veryst Solution

Veryst Engineering has extensive expertise in material model selection and calibration for polymers for most major FE packages, including Abaqus, ADINA, ANSYS, LS-DYNA, COMSOL Multiphysics, and MSC.Marc. Veryst developed two software tools to solve deficiencies in commercial FE programs: PolyUMod®, a suite of advanced user-material models for commercial FE packages designed for polymers, and MCalibration®, a material model calibration tool. Together these packages allow the engineer performing an FE simulation to select and calibrate an advanced material model for polymers (and both are now available through PolymerFEM.com).

Veryst compared the capabilities of different built-in material models in Abaqus, ANSYS, and LS-DYNA to the models available in the PolyUMod library. We tested extruded polyhexamethylene adipamide (Nylon 6/6) in uniaxial tension and compression to characterize the nonlinear visco-plastic response of the material, including the behavior under impact conditions. We then selected and calibrated a material model from each package to all of the experimental data.

We calibrated the following models:

- Abaqus Parallel Rheological Framework (PRF) model

- ANSYS Bergstrom-Boyce (BB) model

- LS-DYNA SAMP-1 model

- PolyUMod Three Network (TN) model

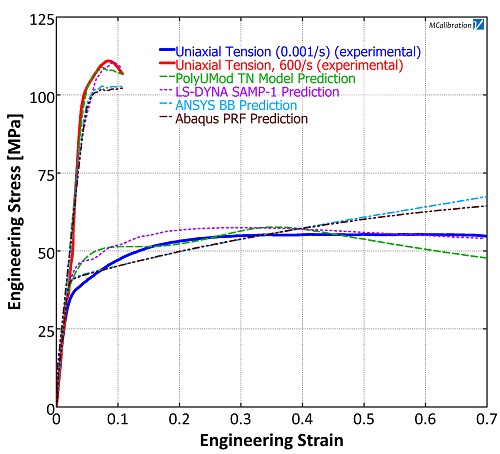

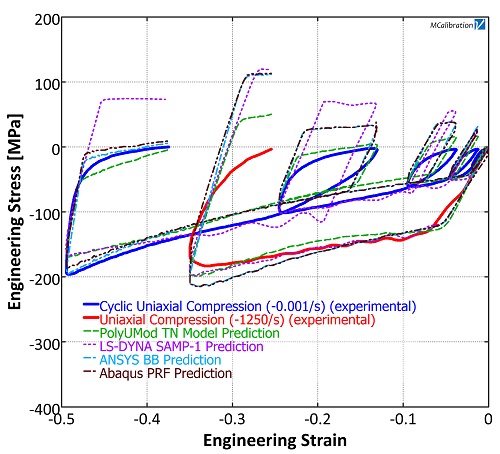

Figures 1 and 2 present the tension and compression results for all of the calibrated material models, respectively. Figure 1 presents the tension data at low (0.001/s) and high (600/s) engineering strain rates, while Figure 2 shows compression results for all the calibrated models at low (0.001/s) and high (1250/s) engineering strain rates.

The low strain rate compression tests utilized cyclic loading with stress relaxation segments prior to unloading.

All the models accurately capture the response of the material in tension. However, the PolyUMod TN model is the most accurate in compression due to the model predictions during the stress relaxation and unloading portions. The PolyUMod TN model more accurately captures the hysteresis and relaxation in the compression tests. Table 1 presents the coefficient of determination (R2) values for each model for tension, compression, and all load cases. The average error for the TN model is 20% lower than for any of the other material models.

Simulation time may play a significant role in the selection of a material model for use in FE simulations. We created a simple FE simulation in each software package to compare the efficiency of the material models. The FE simulation is a tensile test on an ASTM D638 Type IV standard dogbone. Table 2 presents the results for Abaqus/Implicit, Abaqus/Explicit, ANSYS, and LS-DYNA. The PolyUMod TN model performs well compared to the built-in material models, outperforming the Abaqus model.

Our comparison of the different polymer models shows that all four represent the monotonic tensile test data well, but do not perform equally as well when used to predict behavior under different loading conditions. Specifically, the built-in models predict the stress relaxation and unloading segments of the loading less accurately than the PolyUMod TN model.

In addition to the improved predictions, the PolyUMod TN model is available in all major FE packages, while the built-in models are only available in their respective packages (excluding the BB model, which is available in all packages including PolyUMod). Table 3 shows the pros and cons of each model analyzed here.