Veryst Engineering offers a wide range of mechanical testing services, with a particular focus on plastics, polymers, and adhesives. We work with every client to understand what they need to learn from mechanical testing and we design customized plans to meet those needs. For clients requiring test data to be used as finite element analysis (FEA) input, we provide a full suite of testing, material model calibration, and FEA services. To arrange a meeting with one of our mechanical testing or material modeling experts, write to us at testing@veryst.com.

Learn about Testing and Material Modeling Services

Mechanical Testing

Material Test Library

Veryst has a wide range of mechanical testing capabilities available to test your material or product. Here we outline many of the tests that we perform.

Tests by Material Class

Veryst offers a suite of “standard” test programs for characterizing different classes of polymeric materials based on their intended use. In this section, test programs are organized according to the material class.

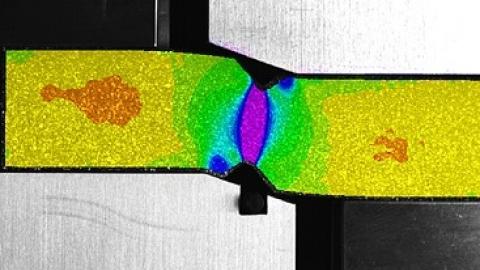

Specialized Tools and Techniques

Veryst Engineering provides a variety of state-of-the-art characterization services, including Digital Image Correlation (DIC), high speed imaging, microscopy, and FTIR spectroscopy and microscopy for our clients.

Specimen Preparation

Veryst can create test samples from raw materials, choosing the specimen preparation method that is most suitable for our clients' material and application.

Material Modeling

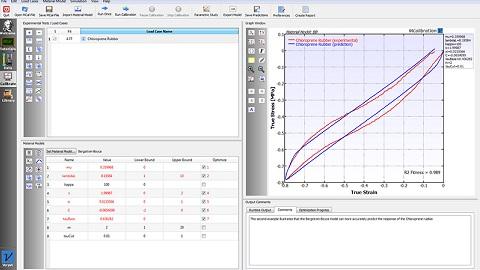

Material Model Calibration

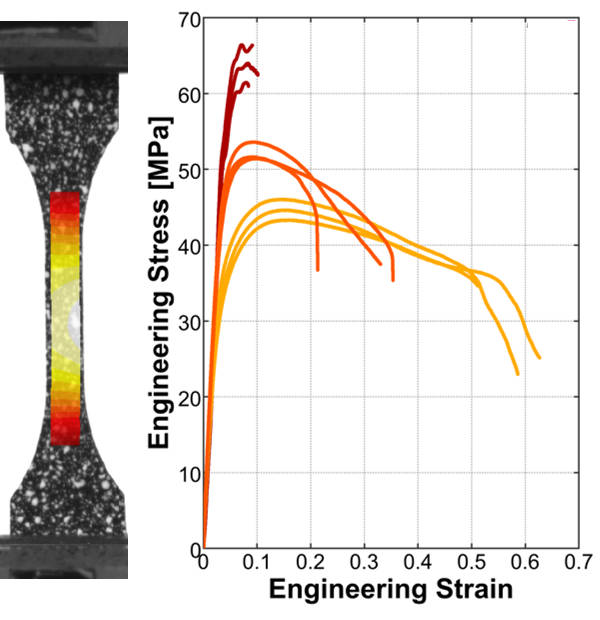

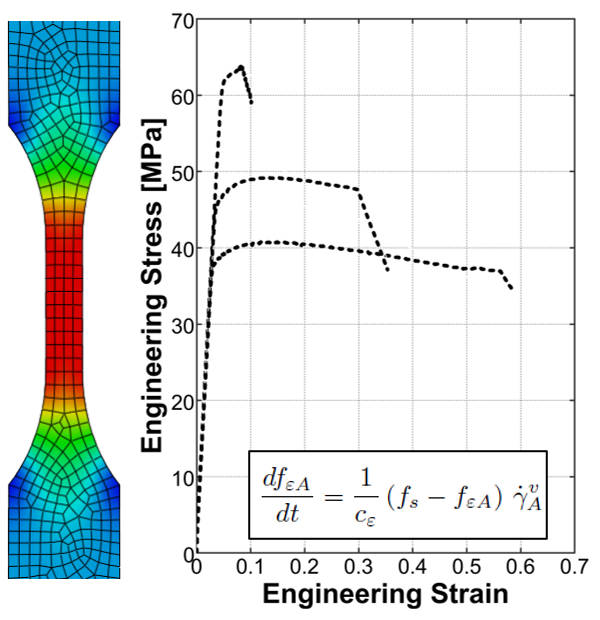

Veryst has extensive experience selecting and calibrating a material model to capture the most important aspects of material behavior for your specific material and conditions during use.

Material Model Validation

Once a material model has been selected and calibrated to the test data, Veryst recommends validating the model by performing a test with a stress state different from any used for calibration.

Finite Element Analysis

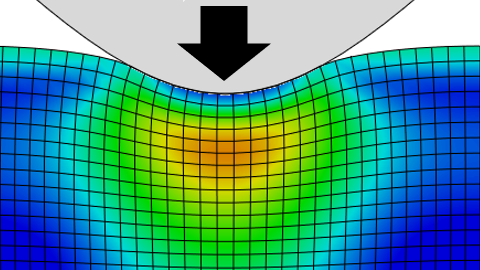

Structural Finite Element Analysis

Veryst offers leading expertise in advanced finite element modeling, particularly for complex, nonlinear problems. We can address problems that other finite element analysis consultants either cannot or are not sufficiently experienced to do well.

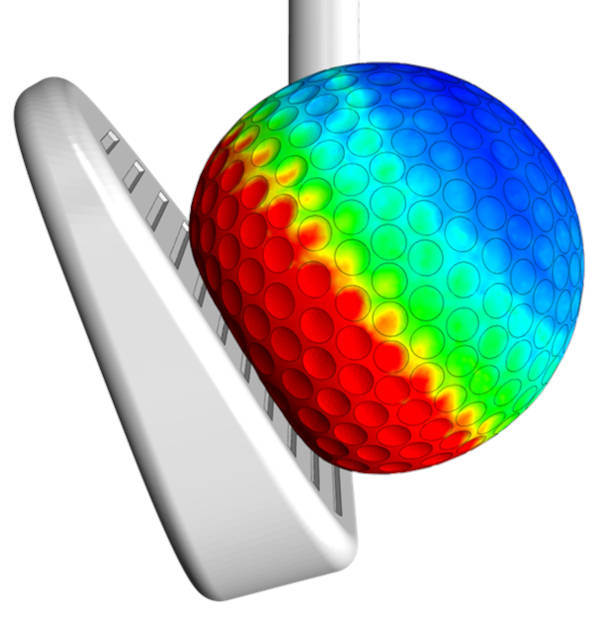

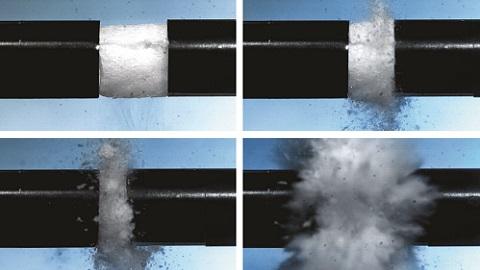

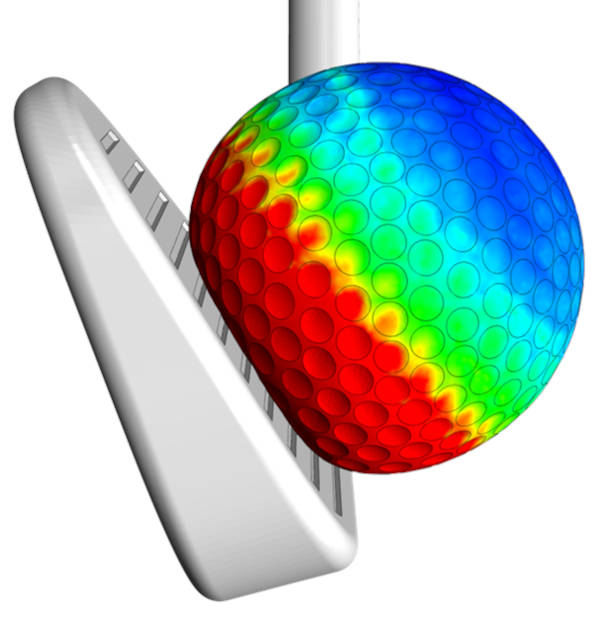

Impact Simulation & Testing

Veryst offers expertise in simulation and testing of impact events with specialties including transient simulations, high strain-rate material characterization, modeling of failure mechanisms, and data processing and analysis. Veryst has served a wide range of industries in this area, such as consumer electronics, sports equipment, consumer appliances, and petrochemical engineering.