Veryst Engineering has extensive experience in impact simulation and testing. We provide a wide-range of services for impact applications, focusing on the following areas.

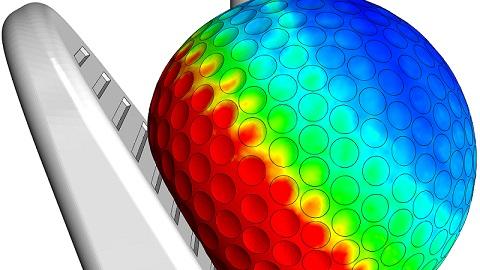

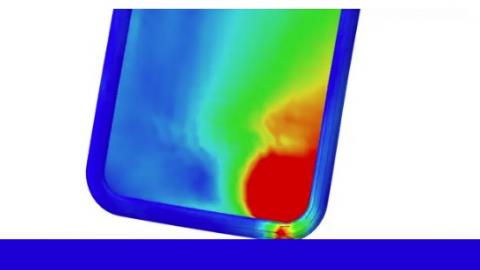

Explicit Simulation

Impact events are transient and often require explicit finite element (FE) simulations. Veryst has extensive knowledge in impact modeling and specializes in the optimization of explicit finite element models for impact simulations with advanced FEA codes including Abaqus, ANSYS Explicit, and LS-DYNA.

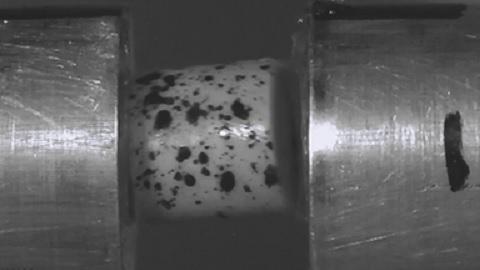

High Strain-Rate Material Characterization

Materials experience very high strain rates (100/s to >1,000 1/s) during impact events. Accurate material characterization at similar high strain rates is essential to model material behavior accurately. Veryst has developed a set of comprehensive, state-of-the-art, experimental capabilities, including drop towers and custom test machines. Veryst also offers material model calibration and validation with high strain rate testing.

Impact Testing and Validation

Veryst offers custom impact testing on polymer products and systems to validate FE simulations.

Modeling of Failure Mechanisms

Veryst provides advanced options for failure prediction with material failure models from the PolyUMod® Library—models that are otherwise not available through commercial FEA codes. Veryst also has extensive experience in modeling the failure of connections and mechanisms, such as bolts, joints, and snap fittings.

Data Processing and Analysis

Explicit simulation produces datasets that are both large and noisy. Veryst specializes in techniques such as data truncating and filtering that extract desired information without distortion or aliasing, as well as advanced programming and scripting that make data processing an automatic part of the simulation.

Veryst’s impact simulation practice has served clients from many industries, including consumer electronics, sports equipment, consumer appliances, automotive, aerospace, and petrochemical engineering. For further information, write to us at contact@veryst.com.