Veryst's clients are often at the leading edge of industry, working with materials and applications that require highly precise and sophisticated testing techniques. Veryst has the expertise to design and build custom test systems to perform the necessary tests and provide our clients with the information they need.

Many of our clients are interested in purchasing our customized test systems for their own use. Below we describe two of our most commonly requested test systems. Please contact us to discuss how we can design and build customized test equipment to meet your needs.

Veryst Drop Tower

Veryst has developed a custom-designed drop tower (patent pending) for conducting high strain rate uniaxial tension and compression tests. Veryst's Drop Tower Model 19A is a unique and versatile test system that can be used to measure accurately the high-rate stress-strain response of elastomers, thermoplastics, foams, engineering composites, thermosets, and biomaterials. The system comes with separate test fixtures for direct measurements of tension and compression and Veryst can design custom fixtures for other loading modes, such as simple shear, as well.

Feature of the test system:

- designed to minimize dynamic vibrations for all polymer materials, from soft elastomers and foams to stiff thermoplastic composites

- uses high speed video to record deformation history

- uses digital image correlation (DIC) to record the strain field

- uses dynamic load cells to record force measurements

- is capable of large deformation measurements, up to an engineering strain of 500% in tension

- includes custom software for combining the measured stress and strain data into a unified data file in csv-file format

- can be expanded with additional test fixtures designed for custom testing.

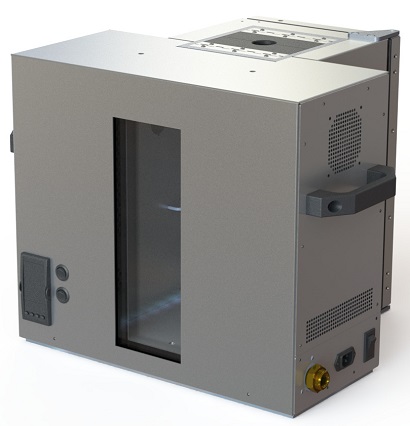

Optional Temperature Chamber

The temperature chamber is an optional supplement to the drop tower to enable testing at elevated and sub-ambient conditions. The chamber uses electrical resistive heating and liquid nitrogen cooling.

Features of the temperature chamber:

- designed to provide a load cell-limited temperature range of -50°C to 100°C

- includes a PID temperature controller with auto-tune

- uses forced air convection, which provides temperature stability and reduces thermal gradients

- includes triple-pane safety glass with an integrated defrosting grid to ensure a clear view of the specimen during elevated and sub-ambient testing

- features an electronic interlock that disables heating and cooling while the rear access door is open, for safe specimen replacement.

Veryst will assemble and install the drop tower in your facility and provide onsite training, a comprehensive user's manual, and additional technical support to ensure your team is getting the most value from this system.

If you are interested in learning more about how a custom drop tower can meet your testing needs, please write to us at testing@veryst.com.

Veryst Ball Impact Test System

Veryst has developed a custom-designed ball impact test system to characterize the high-rate response of soft polymers and validate calibrated material models. This versatile test is designed to measure the viscoplastic response of any thin material in a multi-axial stress state at high strain rates.

In the test, a stiff sphere (typically steel) of known mass and diameter is dropped from a known height onto a sample of the material. Force is measured underneath the sample and the experiment is analyzed in the MCalibration® software. (originally developed by Veryst) The results are used to validate a material model calibrated with uniaxial data and can be used to determine the amount of energy absorbed. The test results can also be used in MCalibration to calibrate a suitable material model using an inverse finite element approach.

Test system features:

-

utilizes a quick-release ball drop mechanism

-

is capable of testing thin layers of most elastomers and foams

-

is able to create a multiaxial compressive stress state with an effective engineering strain rate that can exceed 10,000/s

If you are interested in learning more about how a custom impact test system can meet your testing needs, please write to us at testing@veryst.com.