Technical Challenge

Fiber-reinforced composite materials are becoming more widely used in advanced applications as they provide high strength with minimized component weight. For example, the Boeing 787 airframe is largely composed of carbon fiber reinforced polymers (CFRP), a composite material particularly common for high-performance structural applications. CFRP laminates are composed of layers of carbon fibers held together by a matrix, typically an epoxy. Each layer provides reinforcement in a particular direction, and when these layers are laid together in different directions the final laminate possesses unique anisotropic stiffnesses and strengths.

This can be a significant engineering advantage, as the mechanical properties can be optimized for a particular application.

However, the unique anisotropic properties of composite materials can also complicate the testing, material modeling, and analysis of a design, particularly its failure prediction. Thorough and specialized testing is required to measure appropriately these anisotropic mechanical properties.

Veryst Solution

Veryst characterized a CFRP plate using test methods that exceed relevant ASTM standards.

We cut samples from an upcycled CFRP plate and tested various orientations in tension, compression, and shear.

Tension

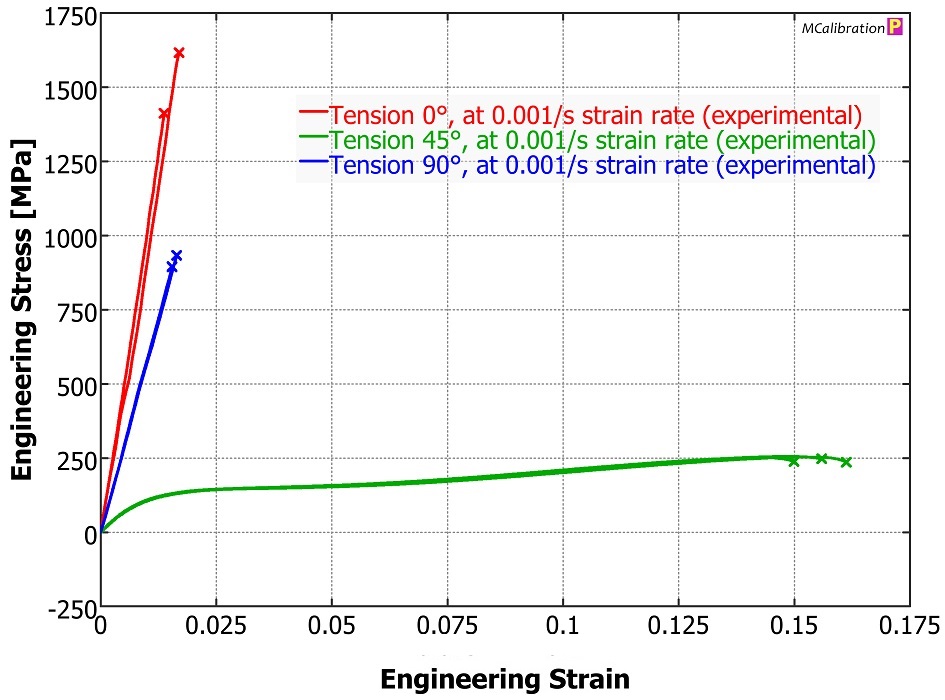

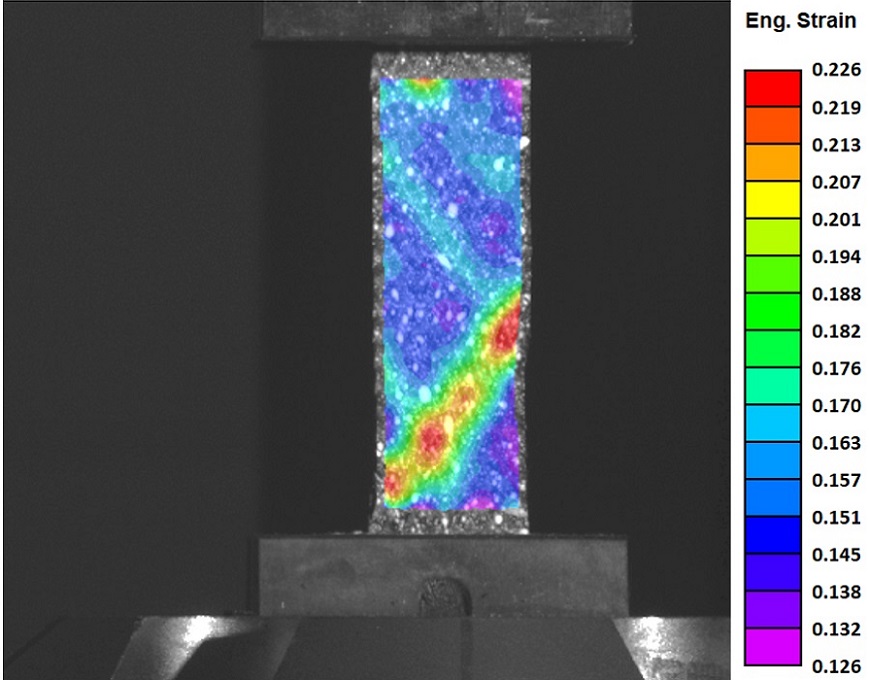

Veryst tested the CFRP plate in tension using full field digital image correlation (DIC) to measure strain. These tests were performed in orientations of 0°, 45°, and 90° following a procedure that exceeds the ASTM D3039 standard commonly used for these materials. The 0° and 90° samples were tested with additional FR4 end-tabs that were bonded with a high-strength structural adhesive, as failure at the grips is common. End-tabs were not necessary for the 45° samples, which all failed in the gage length.

As expected, the 45° orientation experienced the most elongation and lowest stiffness (see Figure 1). The 0° orientation samples had the highest stiffness and failure strength. The 90° samples had a stiffness similar to that for the 0° samples but with significantly lower failure strength.

These results indicate that the composite plate has one superior orientation, although the composition and properties appear to be nearly symmetrical.

The plate shows a 64% increase in stiffness along the 0° direction compared to the 90° direction and an almost 600% increase compared to the 45° direction. Conversely, there is a 10x increase in elongation to failure in the 45° orientation compared to both the 0° and 90° directions.

Compression

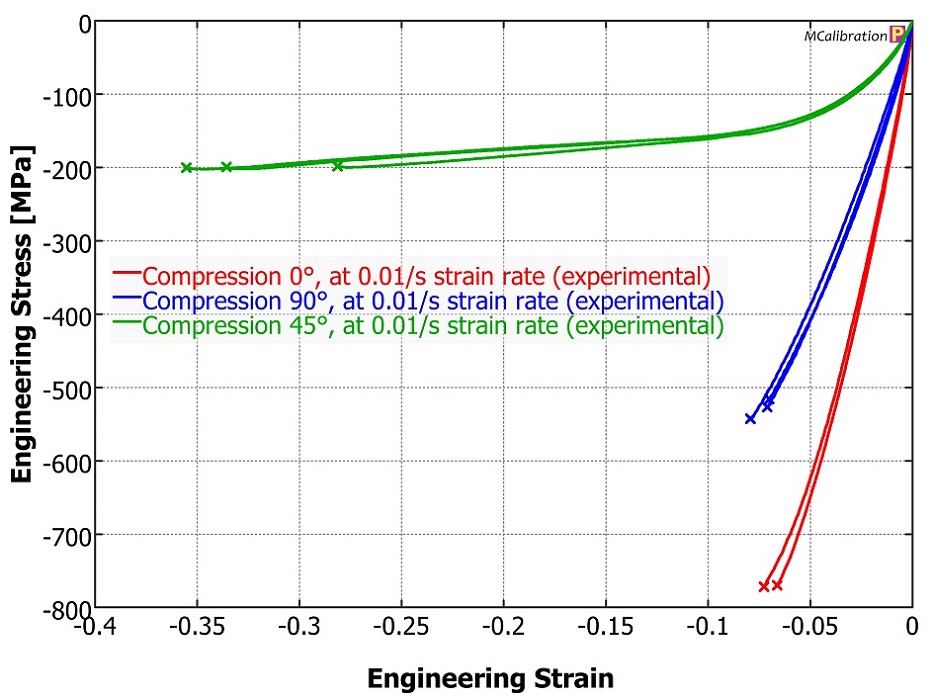

Veryst performed compression tests of the plate using an ASTM D6641 standard compression fixture. As in the tension tests, the 45° samples had the most elongation and a higher failure strain (see Figure 2). The 0° samples had the highest stiffness and failure strength. The 90° samples had a similar stiffness but lower failure stress than the 0° samples.

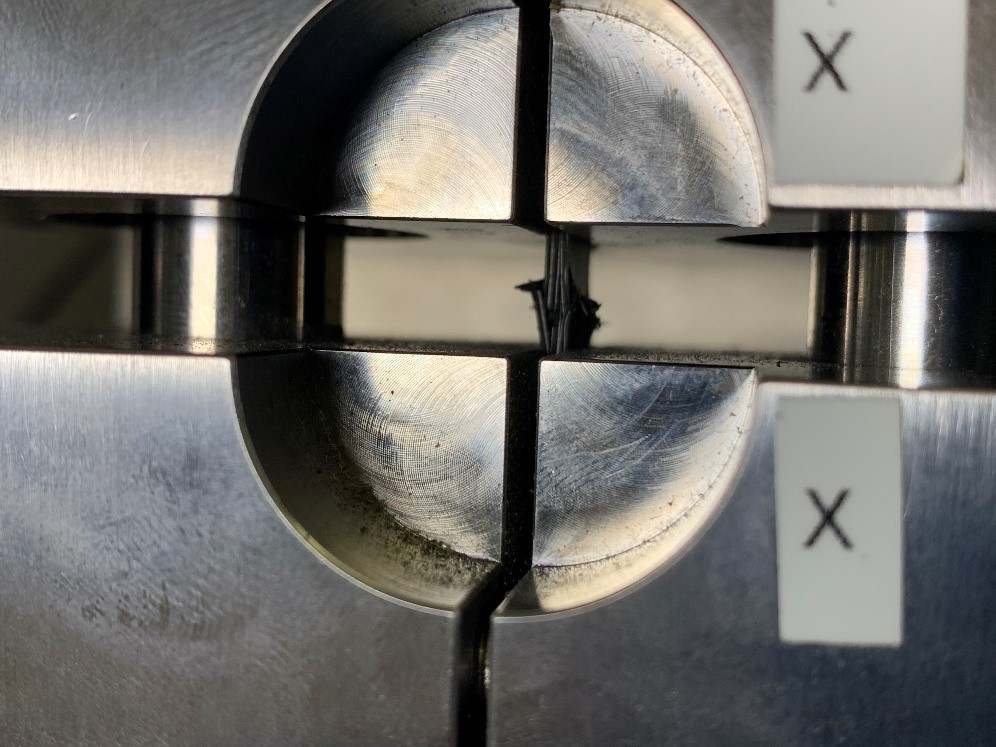

The ASTM D6641 specialized compression test fixture was effective in capturing the compressive failure of the CFRP plate in all three orientations.

The composite panel has a 45% increase in stiffness along the 0° direction compared to the 90° direction and an almost 400% increase compared to the 45° direction. Conversely, there is an almost 5x increase in elongation to failure in the 45° orientation compared to both the 0° and 90° directions.

Figure 2. Compression test results and image of sample failure during test

Shear

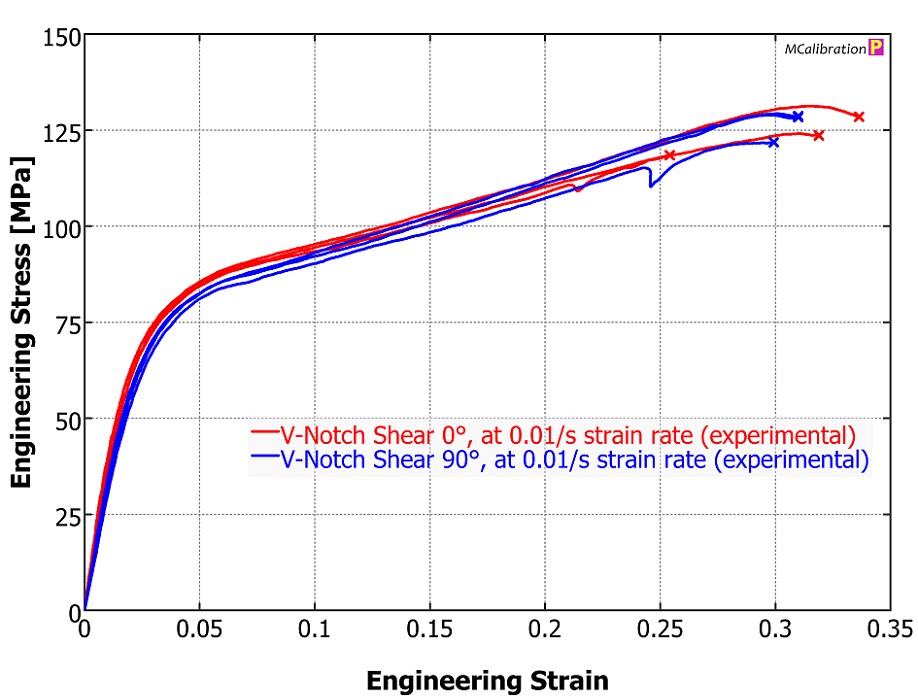

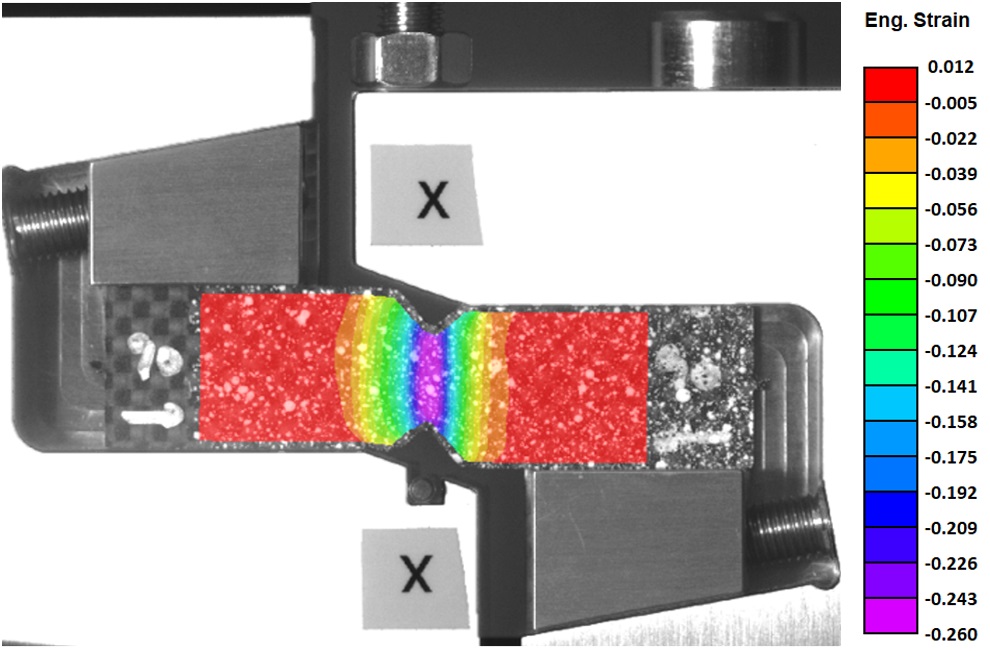

Veryst tested the plate in shear with an ASTM D5379 test geometry and full-field digital image correlation to measure strain. Veryst tested the 0° and 90° orientations and used this data to obtain shear stiffness and strength.

The two orientations exhibited nearly identical behavior, as shown in Figure 3.

Figure 3. V-notch shear test results and 90° sample with speckle pattern for DIC analysis

These tension, compression, and shear tests can be used to characterize most composite materials. These tests measure the anisotropic stiffness, strength, and failure stress/strain properties of a laminate, which are essential for the analysis of a composite component. Further steps to improve the test plan would include testing intermediate orientations, such as 67.5° and 22.5°, as well as validation testing.

We can further use this test data to calibrate anisotropic constitutive models for use in finite element (FE) simulations. Veryst has extensive experience selecting and calibrating material models. For more information, visit our material model calibration section.