Technical Challenge

Generative design tools, such as topology optimization, coupled with additive manufacturing (AM) enable the production of complex structural parts with excellent stiffness-to-weight and strength-to-weight ratios. The way these parts are joined into an assembly is as important as the parts’ geometry. In many cases, adhesive bonding may be a better option than mechanical fasteners for assembling highly optimized structures, given that adhesive bonds are generally lighter weight and distribute stress more evenly.

The shape and size of the bonded areas is something that needs to be considered during the part optimization if a generatively-designed part is to be adhesively bonded into an assembly. Too much bond area will negate the weight savings achieved by using topology optimization and additive manufacturing. Too little adhesive in the wrong places will result in an assembly where the adhesive bond is a weak link in the structure.

Veryst Solution

Veryst used topology optimization to design an additively manufactured aluminum bracket for adhesive assembly and then used cohesive zone modeling to predict the strength of the bonded joint.

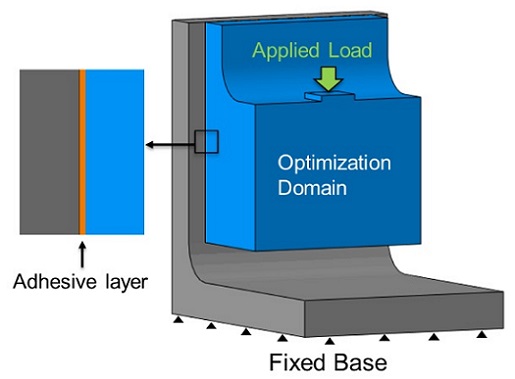

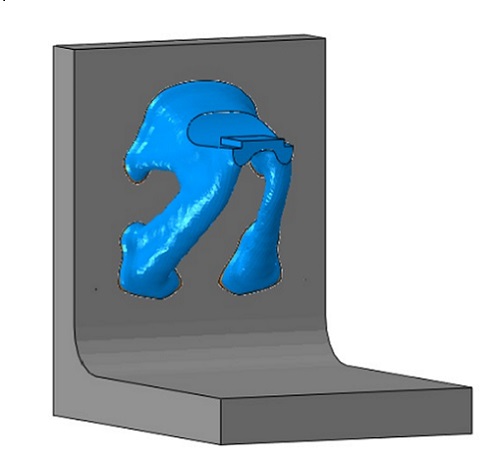

The optimization problem (Figure 1) involved the generation of an aluminum bracket that is vertically mounted on an aluminum frame structure (gray) to support a vertical load (green arrow). The bracket had to fit within the space defined by the optimization domain (blue). We placed a thin adhesive layer between the frame structure and optimization domain. The optimization objective was to maximize the stiffness of the structure while reducing the mass of the optimization domain by 90%. The overhang angle was limited to a maximum value of 45° so that the part could be additively manufactured without supports using direct metal laser sintering (DMLS). The generated bracket design is shown in Figure 2. The bracket mounts to the frame structure via three separate bonding areas that have complex organic shapes perfectly suited for additive manufacturing.

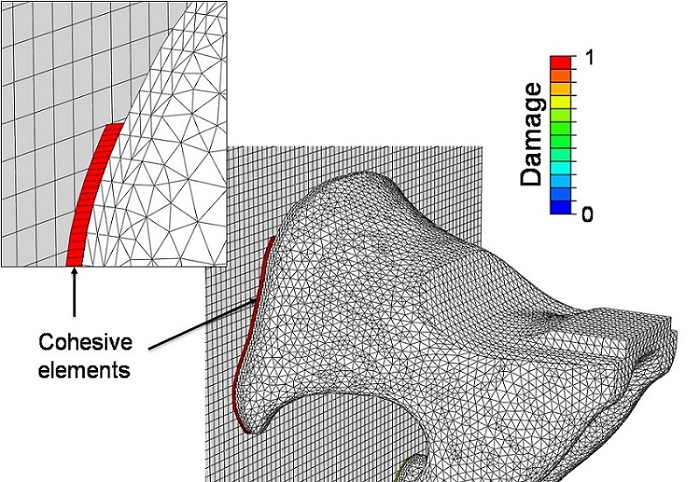

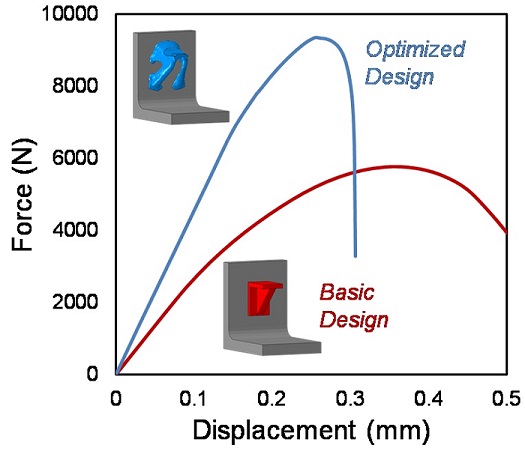

Topology optimization optimizes the elastic response of the structure but does not predict the ultimate load at which the adhesive joint will fail. Veryst used cohesive zone modeling to predict the ultimate strength of the adhesive assembly. Figure 3 shows a snapshot of the simulation after the onset of adhesive failure. The predicted force-displacement curve is shown in Figure 4, along with the predicted force displacement curve for a basic bracket design with equal mass. The optimized design is 68% stiffer and 62% stronger than the basic design.

This case demonstrates that the combination of topology optimization, additive manufacturing, and cohesive zone modeling can enable the design, analysis, and production of superior adhesively bonded structures.