Technical Challenge

Accurately capturing the response of foams is critical to modeling the material for use in finite element (FE) simulations, enabling design engineers to optimize foam components. Polymer foams are complex materials that exhibit enormous sensitivity to applied loading and strain rates. As applied strain rate increases, polymer foam materials stiffen more than bulk polymers, presenting challenges in both testing and modeling. Additionally, foams can exhibit large differences in stress relaxation at different strain rates.

Veryst Solution

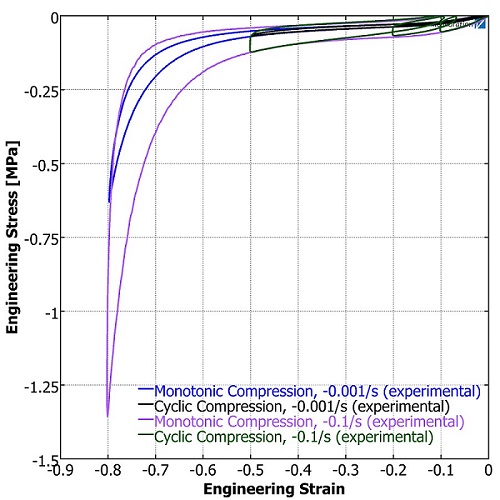

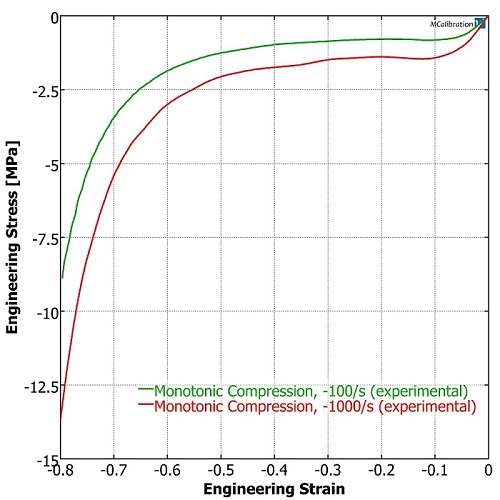

Veryst Engineering has developed high strain rate testing and material modeling capabilities to characterize and implement models in commercial FE software. As an illustration of the strain-rate-dependence of a urethane foam, Veryst tested the material in compression over five decades of strain rate. Figures 1 and 2 show the results from the tests, demonstrating the extreme strain rate dependence – the material is 100 times stiffer at 1000/s compared to 0.001/s.

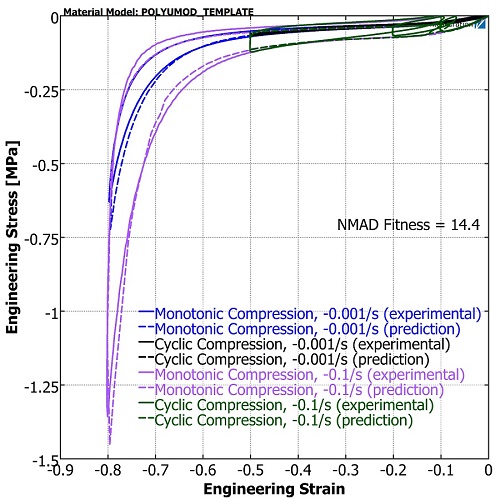

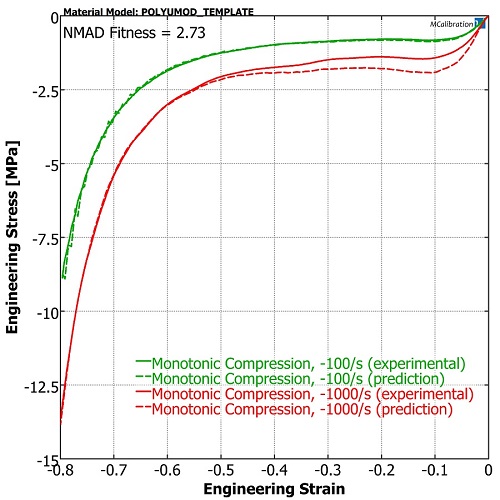

Selecting and calibrating a material model to the experimental data is difficult due to this extreme strain-rate dependence. Veryst developed the PolyUMod® Responsive Elastomer Foam (REF) material model specifically to capture the response of this class of materials.

Figures 3 and 4 show the results of the model calibration from MCalibration®. The calibrated model is in excellent agreement with the experimental data, and the material model is available for use in Abaqus/Explicit and LS-DYNA. (Both PolyUMod and MCalibration were developed by Veryst and are now available through PolymerFEM.com.)

Veryst recommends validating a calibrated material model with test data that uses a complex stress state. For soft materials like this urethane foam we recommend performing a ball impact test. The test is then simulated with the calibrated material model and the results are compared to the experimental data.

Figure 5 shows a video of the effective strain rate in the material during the FE simulation. The sample experiences extremely high strain rates, over 10,000/s.