Technical Challenge

Many polymers are prone to deform slowly over long periods of time when subjected to sufficient static stress, a phenomenon known as creep. Over time, the deformation can grow so large that the part no longer functions as intended.

Our client wanted to redesign a device to meet a two-year shelf storage requirement but did not have the time to run a two-year creep test.

Veryst Solution

Veryst used time-temperature superposition (TTS) to characterize quickly the long-term creep performance of the material from which the part is made. TTS can predict the mechanical response of polymers at timescales not accessible using conventional mechanical testing.

The underlying principle of TTS is that the mechanical response of a polymer at an elevated temperature for a short time is equivalent to the mechanical response at a lower temperature for a long time. The TTS principle relies on the materials being thermorheologically simple (TRS) materials, and most polymers are TRS at low to moderate strains.

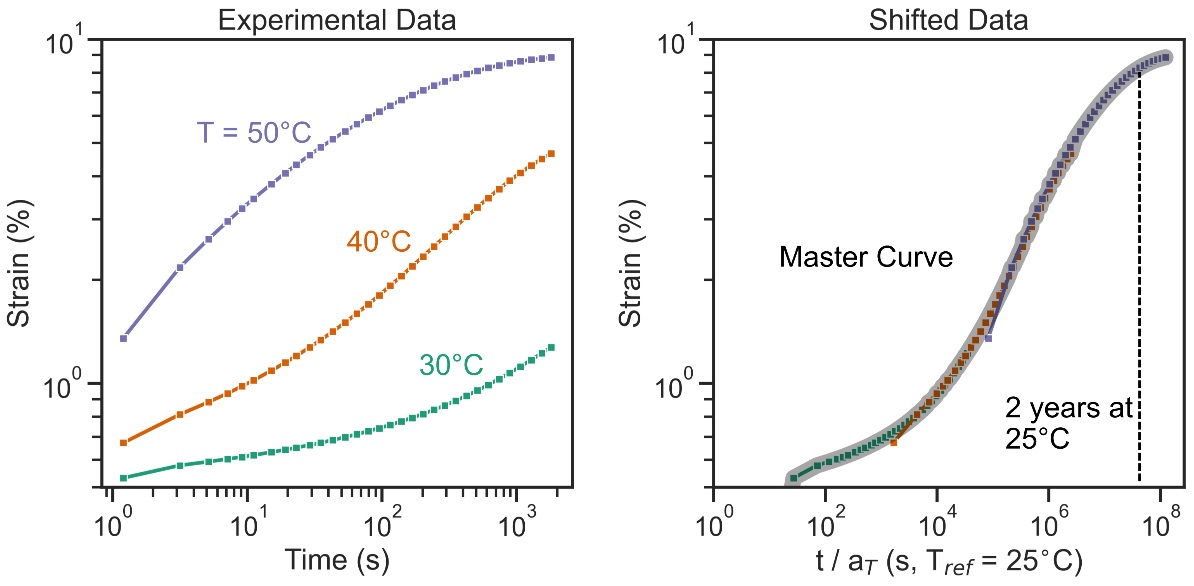

Creep strains from tests at multiple temperatures are shifted along the time axis by a shift factor aT to generate a master curve that predicts the creep response for times up to several years or even tens of years. This process is shown in Figure 1. Veryst measured the creep strain at a stress of 10 MPa versus time at 30°C, 40°C, and 50°C. These three curves were then shifted to create a master curve.

For the client’s material, Veryst generated a master creep curve that predicts the amount of strain up to three years. Our client used the creep predictions from TTS to redesign the part to meet the creep requirement, saving two years of testing and subsequent design iteration that would have been otherwise required to meet the specification.