Technical Challenge

A specialized industrial product began failing during use due to debonding of an adhesive joint, resulting in significant customer returns. Veryst was asked to determine the root cause of the failure and identify pathways to improve product reliability.

Veryst Solution

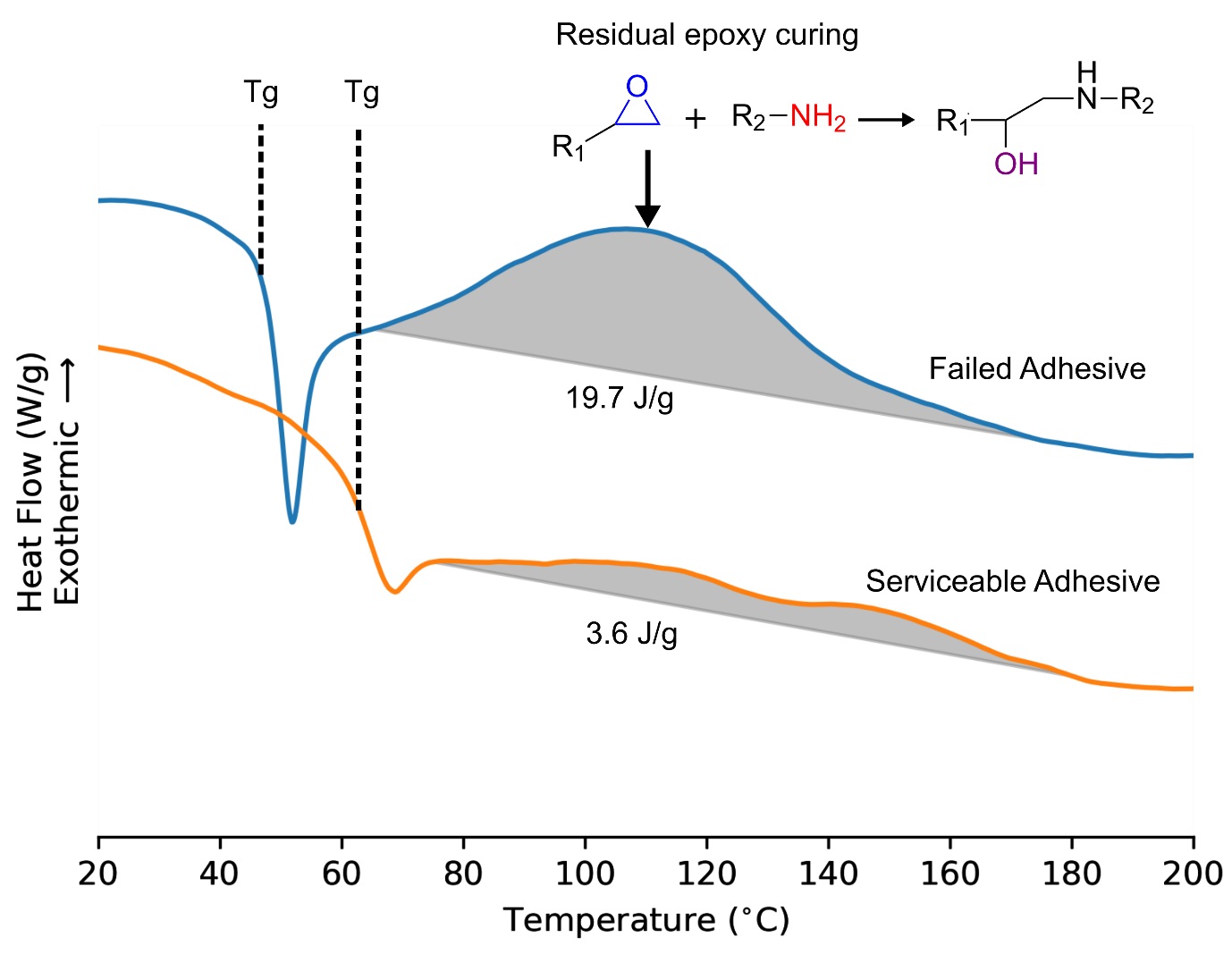

Veryst used differential scanning calorimetry (DSC) to analyze adhesive samples from two devices: one that failed early in use and one that had not failed during use. DSC is a thermal analysis technique that is useful for analyzing polymers because it can measure both the glass transition temperature and melting point from only a few milligrams of material. For thermosetting polymers such as most structural adhesives, DSC can identify if an adhesive is fully cured.

Figure 1 shows the results from the DSC scans. In both cases, the temperature was ramped from 20° to 200°C. The step in the heat flow vs. temperature curves indicates the glass transition temperature (Tg), and the increase in the heat flow (an exothermic peak) represents progression of the curing chemical reaction. A larger exothermic peak indicates that the adhesive was not fully cured during production and the material continued to cure during the DSC testing.

When we compared the adhesives in failed devices to adhesives in serviceable ones, we made two observations:

- The glass transition temperature of the failed adhesive is much lower than the glass transition temperature of the serviceable adhesive (48°C vs. 63°C).

- The curing peak for the failed adhesive is much larger than the curing peak for the serviceable adhesive (19.7 J/g vs. 3.6 J/g).

Both observations suggest that the adhesive in the failed devices was not sufficiently cured during production, and only fully cured during the DSC test. Armed with the information provided by DSC testing that the adhesive processing was the most likely root cause of failure, subsequent investigation revealed that the curing oven was not heating the samples evenly, resulting in poorly-cured adhesive. The client was able to rectify the issue quickly and restore the production line to working order.