3D BioLabs, LLC is revolutionizing organ transplantation and complex surgical reconstruction by developing a scalable platform technology to address the human donor organ shortage. Led by Dr. Joseph “Jay” Vacanti—Professor of Surgery at Harvard Medical School—3D BioLabs partnered with Veryst for deep expertise in fluid mechanics, structural mechanics, and materials science to translate a visionary tissue device concept into robust engineering reality.

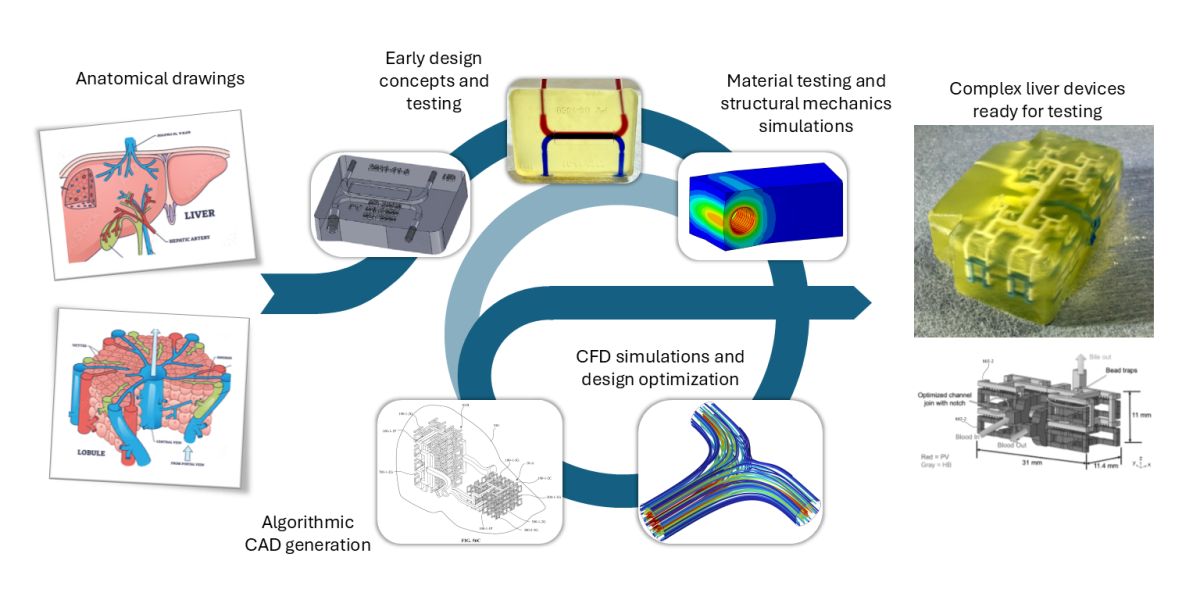

The collaboration began with anatomical drawings and Dr. Vacanti’s forward-looking vision (Figure 2). Veryst first ensured 3D printing reliability for biomaterial inks, then developed initial two-channel prototypes that enabled the 3D BioLabs team to refine their surgical implantation protocol. Next, Veryst characterized biomaterial properties and simulated mechanical loads, ensuring the devices made from the printed biomaterials could withstand handling and use.

As development progressed, Veryst built a design paradigm for intricate internal channel networks to promote uniform blood or culture media distribution. The team used advanced Computational Fluid Dynamics (CFD) simulations to optimize junctions, ports, and plumbing—critical for maintaining physiological wall shear stresses and blood health.

Device iterations advanced to complex, fractal-like networks with multiple bifurcations for superior nutrient and waste exchange across larger tissue volumes. Veryst automated CAD generation for these geometries to accelerate design cycles and ensure accuracy, while 3D BioLabs successfully printed and tested each new device iteration.

This collaboration met aggressive R&D milestones and led to multiple peer-reviewed publications and patent disclosures—one already granted—demonstrating how multidisciplinary engineering and biomedical science can drive transformative advances in organ replacement technology.

References:

3dbiolabs.com

Tyler Lieberthal, Tatevik Sahakyants, Naomi Szabo-Wexler, Matthew Hancock, Andrew Spann, Mark Oliver, Scott Grindy, Craig Neville, Joseph Vacanti. (2024) Implantable 3D printed hydrogels with intrinsic channels for liver tissue engineering, PNAS, 121, e2403322121 (link https://doi.org/10.1073/pnas.2403322121)

Tatevik Sahakyants, Tyler Lieberthal, Carly Comer, Matthew Hancock, Andrew Spann, Craig Neville, Joseph Vacanti. (2023) Rodent Model for Orthotopic Implantation of Engineered Liver Devices. Tissue Engineering Part C: Methods, 29, 20-29. (link https://doi.org/10.1089/ten.tec.2022.0174)

Joseph Vacanti, Batzaya Byambaa, Carly Comer, Matthew Hancock, Tyler Lieberthal, Tatevik Sahakyants, Andrew Spann, Craig Neville. (2025) Systems and methods fabricating a microchannel vascular network device and seeding a microchannel. US Patent 12,351,827 B2 (link https://ppubs.uspto.gov/pubwebapp/external.html?q=(12351827)&db=USPAT&t…)

Joseph Vacanti, Matthew Hancock, Mark Oliver, Andrew Spann. (2019) Additive manufacture of complex implantable living devices. US Patent Application 16/424,374 (US20190358367A1, link https://patents.google.com/patent/US20190358367A1/en)