Technical Challenge

An automotive product was redesigned using an aluminum-polyethylene structure to replace a steel part, resulting in a significant weight reduction. However, the part failed at the polyethylene-aluminum adhesive joint. The durability of the interface needed to be improved to realize the benefit of the reduced weight.

Veryst Solution

Polyolefins such as polyethylene (PE) do not form strong bonds with structural adhesives due to their surface chemistry, and joints that contain PE adherends are typically low-strength and not durable. Veryst recommended using corona discharge plasma to modify the surface chemistry of the PE adherend, a process often called corona treatment.

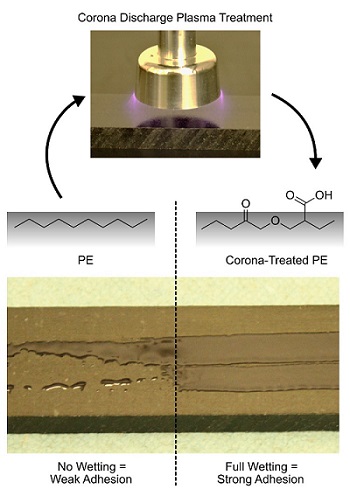

The low-temperature plasma created by corona treatment oxidizes the surface of the PE, creating polar functional groups. The polar groups improve the wetting of the epoxy and allow the PE to create a stronger bond with the epoxy. The corona treatment process is shown in Figure 1.

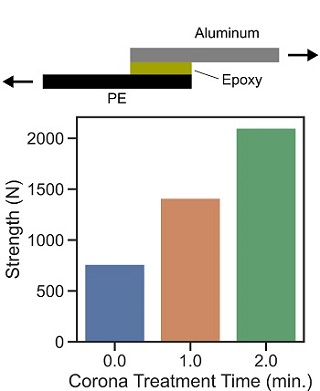

We measured the lap shear strength of PE and aluminum (Al) joints with varying levels of corona treatment. We found that the shear strength of the joint increases by 85% after 1 minute of corona treatment and 175% after 2 minutes of treatment (Figure 2).

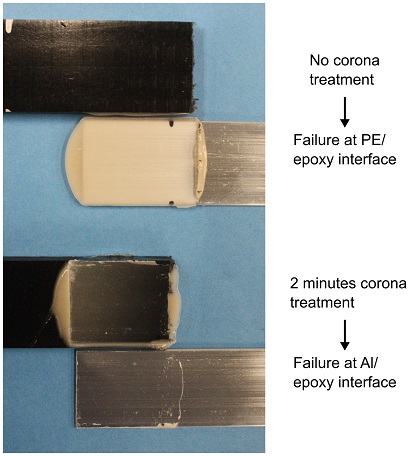

In addition, untreated PE/Al joints fail at the PE/epoxy interface, while corona-treated PE/Al joints fail at the Al/epoxy interface, demonstrating the dramatic improvement in PE/epoxy bond strength (Figure 3).

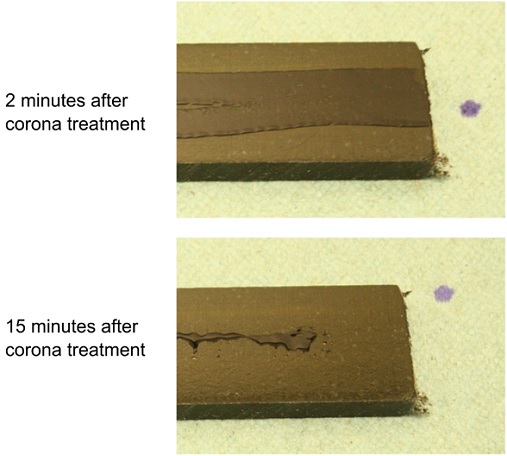

While corona treatment significantly improves the bond strength of PE joints, the treated surface only lasts a limited amount of time because the oxidized groups on the surface are reactive. This is demonstrated in Figure 4. After 15 minutes, the test ink beads up and does not wet the PE surface, demonstrating that the PE surface chemistry has returned to its original state.

Veryst worked with the manufacturer to optimize the production process and institute a quality control program to ensure that during production, the polyethylene adherends would maintain an oxidized surface prior to bonding.

The strong and durable aluminum/polyethylene joints allowed our client to realize the lightweighting gains from the material change.