Technical Challenge

Whole bones are composed of multiple materials with different material properties, including complex structures and geometry. Accurately predicting the mechanical response of whole bones in impact scenarios can be challenging with these complexities.

Veryst Solution

Veryst conducted high rate three-point bending tests on whole porcine ribs as well as other complex geometries (biological or synthetic).

Veryst prepared specimens by removing all soft tissue and periosteum from the surface of the bones prior to testing, and measured along the shaft and costal groove to determine the average cross-sectional area of the center portion of the rib.

We performed the tests on a three-point bend fixture with our custom-built drop tower (shown in Figure 2). The tests used a 25 kg impactor at 1 m/s.

We recorded the test with a high-speed camera at 20,000 fps and used digital image correlation (DIC) to calculate the displacement of the impactor while force was measured using a dynamic load cell attached to the impactor.

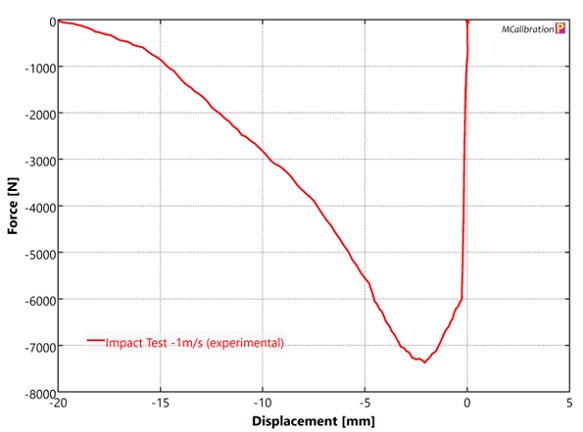

We are able to extract a force displacement curve for the whole bone from the DIC data and the dynamic load cell. The force displacement curve is shown in Figure 3.

This data can be used to help calibrate material models for biological systems, determine material response of synthetic replacements, or validate material models for biological FE simulations.