Technical Challenge

Droplet formation and detachment are fundamental to many industrial, consumer, and biomedical processes—from precision dispensing to printing to spraying in applications ranging from drug delivery to additive manufacturing to fuel injection. Across these applications, precise control of droplet size, timing, and release is critical to achieving consistent performance, efficiency, and quality. Attaining such control requires a deep understanding of the coupled effects of surface tension, viscosity, inertia, and flow conditions that determine how a droplet forms, elongates, and detaches from a nozzle or surface. Capturing these fast, highly nonlinear dynamics presents significant challenges for both modeling and simulation. In this example, we numerically simulate a dripping nozzle to study the physical mechanisms governing liquid thread thinning, pinch-off, and the formation of secondary satellite droplets.

Veryst Solution

The computational fluid dynamics (CFD) experts at Veryst coupled the Navier–Stokes equations with multiphase flow theory to model the flow of two immiscible fluids—air and water—with surface tension and contrasting material properties.

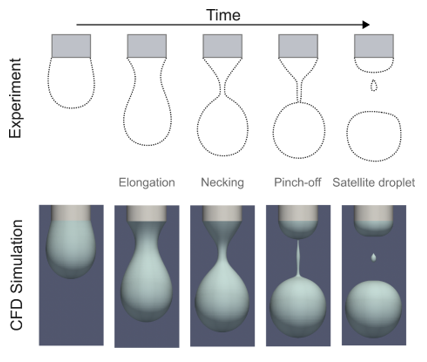

We applied this strategy to simulate a dripping nozzle in ambient air (Figure 1). To achieve a high-fidelity characterization of the involved interfacial dynamics, we implemented a stabilized, residual-based variational multiscale (RBVMS) formulation [1], providing a robust balance between accuracy, stability, and computational efficiency. Our predictions agree well with measurements (Figure 2, data from [2]). The simulation accurately captures key physical behavior, including droplet elongation, necking, pinch-off, and satellite droplet formation.

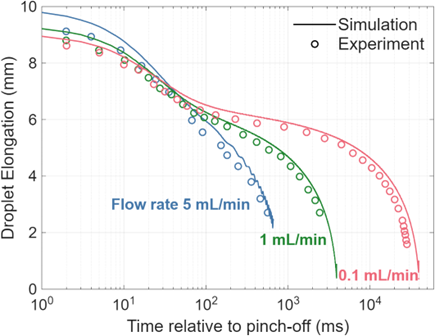

A key control parameter in dispensing systems is the flow rate. Our simulations, validated with experiment over different flow rates, show that while lower flow rates naturally delay pinch-off, the evolution of droplet elongation before detachment depends only weakly on flow rate (Figure 3).

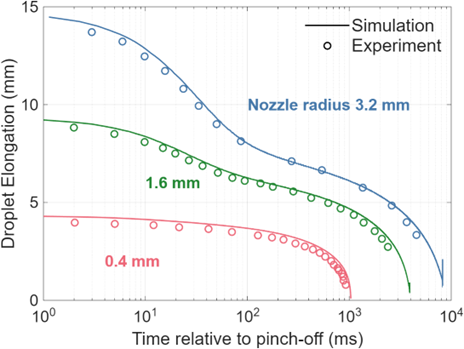

We also examined the effect of nozzle radius on droplet formation at a fixed flow rate (Figure 4). Both pinch-off timing and droplet elongation are sensitive to nozzle radius. These findings highlight how nozzle radius selection can help control droplet formation and dynamics, providing a practical knob for designing dispensing systems that demand accurate droplet characteristics.

Conclusion

Veryst successfully captured the complex dynamics of droplet formation and detachment using high-fidelity multiphase computational fluid dynamics (CFD) simulations. Our results enable engineers to predict and control droplet behavior across a wide range of applications, supporting the design of more efficient, reliable, and high-performance fluidic systems.

[1] H. Gómez, Y. Leng, T. Hu, S. Mukherjee, and V. Calo. “Phase-Field Modeling for Flow Simulation,” in Frontiers in Computational Fluid-Structure Interaction and Flow Simulation, edited by T. E. Tezduyar, Springer International Publishing, pp. 79–117, 2023.

[2] X. Zhang and O. A. Basaran. “An Experimental Study of Dynamics of Drop Formation,” Physics of Fluids, 7 (6): 1184–1203, 1995.