Technical Challenge

Medical devices, combination products, consumer products, and manufacturing processes often include components that slide past each other. These products and processes can fail when the friction forces between the surfaces are too high. For example, factors such as surface roughness, lubrication, material type, heat, humidity, and normal force affect friction.

Standard friction tests typically require large samples and measure forces with a universal test frame, away from the actual friction. This works well on large sheets of material if the sheets mimic the actual manufactured parts. This method is limited if the manufactured parts are more complicated—for instance, if they are post-processed (including lubrication, coatings, surface treatments, and polishing) or the manufactured parts are not flat. Additionally, medical devices often require dual sourcing, so manufacturers must select alternative materials that do not significantly increase the friction between parts in the device.

Veryst Solution

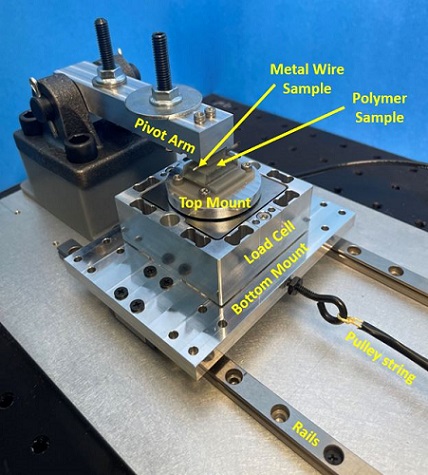

Veryst created a small-scale test fixture to test low friction forces on complicated surfaces in their as-manufactured design, shown in Figure 1.

We use a three-axis load cell close to the friction force to eliminate the error from pulleys or the linear rails, and the normal force is controlled by adding weights to the pivot arm. The pivot arm has a custom-designed holder to hold a small wire (diameter of 1.57mm). For this study, we measured the friction force (and coefficient of friction) between the wire and three different polymer materials.

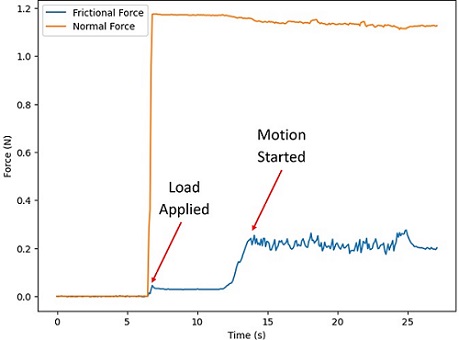

Veryst calculated the coefficient of friction using the measured normal force and the measured friction force from a three-axis load cell. An example test run is shown in Figure 2 and the results are shown in Figure 3.

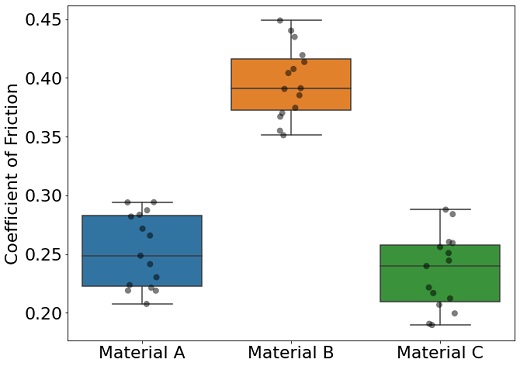

Figure 4 shows the results for three materials. Material A is the current design, and Materials B and C are alternative designs. The box plot shows the results for the coefficient of friction for all three materials. There was a statistically significant difference in the coefficient of friction for the wire rubbing against Materials A and B as compared to Material C (p-value < 0.05).

Conclusion

Small-scale friction testing can be difficult, particularly when the manufactured parts are not flat or small, or they are processed in a way so that representative materials are hard to source accurately. Veryst developed a miniature friction test fixture to measure low frictional forces with high accuracy.

We demonstrated the capabilities of this fixture on three materials used in medical devices. Material B exhibited much higher friction compared to Material A, while Material C had statistically equivalent friction compared to Material A. Thus, Material C was the optimal material to select for dual material sourcing for this application to maintain the friction performance.