Technical Challenge

Light-emitting diode (LED) bulbs offer higher energy efficiency and longer service life than fluorescent and incandescent lamps.

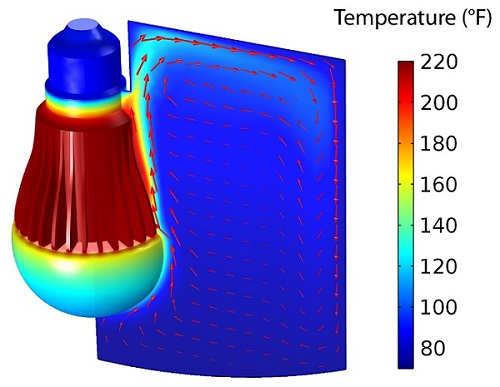

However, both the efficiency and life of an LED will drop when operated at high temperature. Manufacturers design heat sinks with cooling fins into the body of the bulb to reduce the operating temperature.

Given the wide range of possible shapes and sizes of heat sinks, a rapid and effective tool is needed to compare design alternatives and estimate LED temperatures.

Veryst Solution

Veryst developed a conjugate heat transfer finite element model of an LED bulb and surrounding air in an enclosed recessed lighting fixture. Conduction between the LEDs and the bulb body, natural convection in the surrounding air, and radiation between surfaces were included to predict the temperature of the LEDs accurately .

The model provides a number of design insights to inform design decisions. Higher air velocity, greater temperature differential, and more surface area will increase heat flow away from the bulb. These parameters are interrelated and vary over the bulb’s surface.

Using this model, selection of the bulb and heat sink geometry and material can be optimized for the minimum LED temperature possible within manufacturing constraints.