Technical Challenge

Many consumer applications need vibration damping components to protect electronics or other sensitive materials. Various foam materials are commonly used in these applications due to their low price and good vibration damping characteristics. Most foam components, however, have a highly nonlinear viscoelastic response that requires a suitable material model for accurate finite element predictions.

Veryst Solution

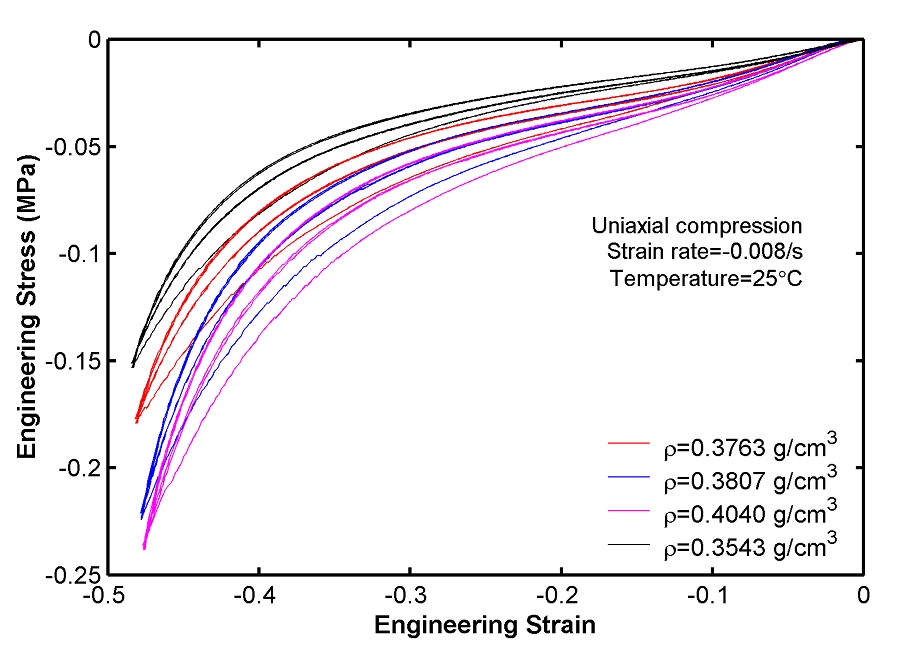

Veryst developed the Microfoam model to predict the response of viscoelastic foam materials. This model is available as part of the PolyUMod® user-material model library, originally developed by Veryst and now available through PolymerFEM.com. This material model can be calibrated to uniaxial compression and tension data at different strain rates and temperatures. One other unique feature of this model is that it takes the void volume fraction as an input parameter. This also makes it possible to use the model to optimize certain features of the foam microstructure, which can be used to guide not only the damping component geometry, but also the damping component material.

The Microfoam model has been used to predict and optimize the geometry of many different consumer products in vibration and drop test applications.