Technical Challenge

High performance liquid chromatography (HPLC) is an analytical technique that uses high pressure pumps to push a liquid mobile phase through a packed column, separating components of a mixture based on their interactions with the stationary phase. HPLC is widely applied in pharmaceutical analysis and quality control, clinical and biochemical assays, food and environmental contaminant monitoring, and forensic and industrial chemistry wherever precise, high resolution quantification of chemical species is needed. Recent developments in HPLC have trended towards columns comprised of smaller, fully porous, spherical particles with monodisperse size distributions. The effect of such changes on

chromatographic performance metrics, including column efficiency and backpressure, is uncertain from empirical evidence alone. The main challenge is decoupling the effects of mean particle diameter, polydispersity, and intraparticle porosity, as these properties emerge naturally from the particle production process and cannot be independently controlled. To circumvent this challenge, multi-scale simulations can provide useful insights into packed-bed design, such as revealing the sensitivity of macro-scale transport and adsorption to micro-scale variations in particle size and intraparticle porosity. Such simulations can help to decouple variable outcomes from processing and manufacturing changes.

Veryst Solution

Veryst used COMSOL Multiphysics® to simulate flow of a four-component mixture through a reversed-phase HPLC column with a known particle size distribution. We coupled bulk mass transfer to pore mass transfer within the particles of a polydisperse population. We then used this model to predict the impact of varying mean particle size and size dispersity on column efficiency and pressure drop.

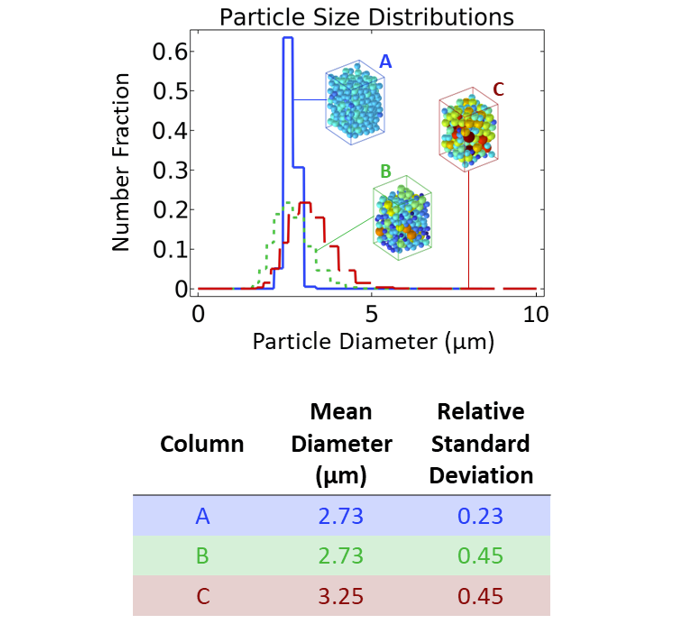

We modeled three columns with distinct particle size distributions, reflecting processing differences in the production of porous silica particles (Figure 1). A finely tuned process results in highly monodisperse populations of small particles (Column A). Slight variations in processing conditions can broaden the size distribution without significantly changing the mean particle diameter (Column B). Yet other changes can lead to simultaneous shift and broadening of the distribution, affecting both mean size and size dispersity (Column C).

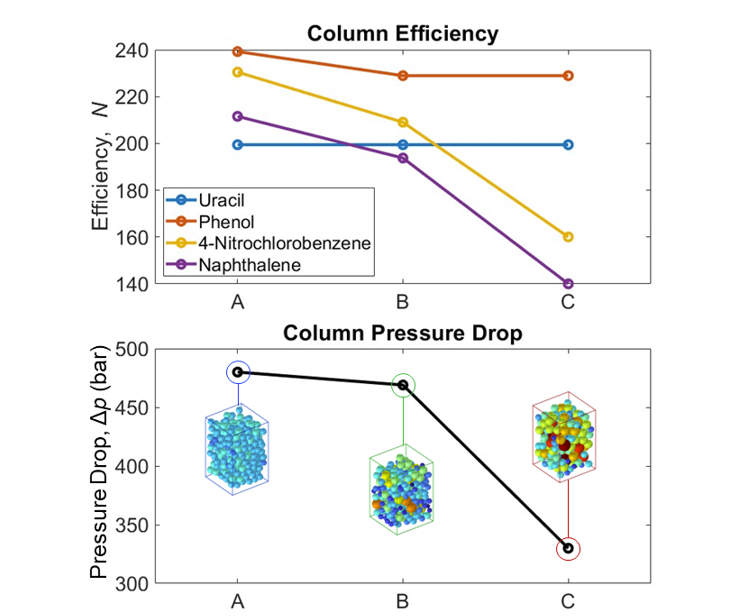

In reversed-phase HPLC, components are separated based on their hydrophobicity (Figure 2). Molecules containing polar moieties (e.g., uracil, phenol, 4-nitrochlorobenzene) elute at a much faster rate compared to organic, non-polar molecules (e.g., naphthalene), which are retained within the column for longer periods. The squared ratio of the mean retention time, tr to the standard deviation, τ, defines the chromatographic efficiency, N = (tr/τ)2. Narrow peaks in the detected signal indicate high chromatographic efficiency (large N), whereas broad peaks indicate low efficiency (small N).

Our simulations reveal that increasing mean particle size or size dispersity generally reduces column efficiency and pressure drop and quantify the impact of each variable independently (Figure 3). Highly polar molecules (e.g., uracil) exhibit weak affinity for the particles and, therefore, show little dependence on the particle size distribution. On the other hand, molecules with more hydrophobic character (e.g., naphthalene) show increased dependence on particle size. Smaller, more monodisperse particle populations (Column A) result in higher efficiency, at the expense of higher pressure drop due to enhanced hydrodynamic dissipation. Conversely, larger, more polydisperse populations (Column B) exhibit lower pressure drop and reduced efficiency due to slower intraparticle diffusion.

Conclusion

Veryst developed a multi-scale model of reversed-phase liquid chromatography to simulate the effect of changes in particle size distribution on chromatographic performance. Our simulations showed that independently increasing particle size or size dispersity reduces column efficiency and column pressure drop. These effects were revealed by coupling macroscopic transport processes at the column scale to microscopic processes occurring at the particle scale. Simulations such as these provide useful insights into the sensitivity of chromatographic columns to particle size and porosity, which directly inform upstream particle production and packing processes. Finally, these insights extend to other systems comprising fixed beds, including catalytic reactors and lithium-ion batteries.