Technical Challenge

Compression springs are employed in a wide range of uses, from industrial equipment to medical devices and electronics, and predicting their behavior is essential to their design. A spring is an accessible, easy-to-undertake problem defined by several parameters, such as wire diameter, number of coils, and free length. Figure 1 shows an example of a helical compression spring design. However, designing a compression spring is an over-constrained problem—a spring design may not be possible given all dimensional, reliability, and spring constant requirements. Additionally, designing a spring to withstand a given load and environment requires several considerations regarding its potential modes of failure.

Using finite element analysis (FEA) to predict spring behavior can yield several important qualities representative of each spring design. However, this involves advanced FEA expertise to carry out and interpret multiple analyses that can be incorporated into spring design.

Veryst Solution

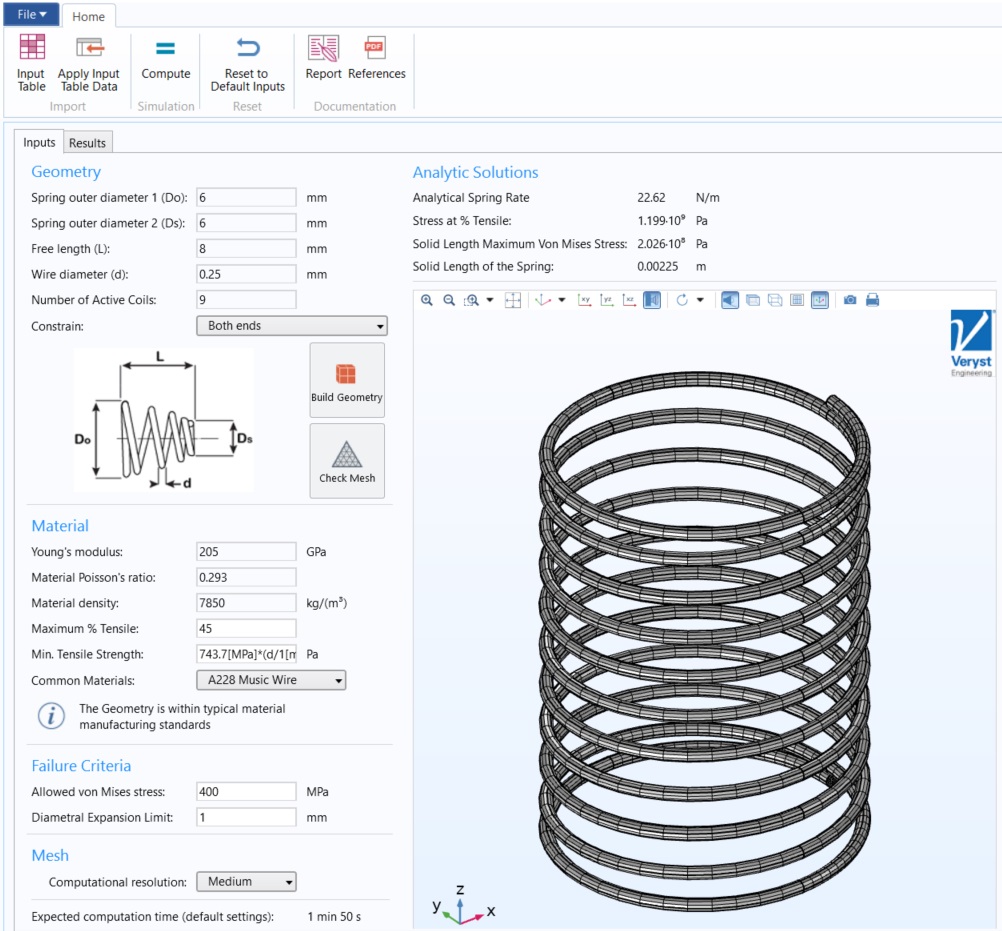

Veryst developed a robust COMSOL Multiphysics standalone application or “app” that simulates the compression of both helical and conical springs, as shown in Figure 2.

Modeling a compression spring with a standalone app enables any user to solve this parameterized problem quickly and elegantly, without any prior FEA experience. Veryst’s app permits the user to specify every dimension of the spring as well as the spring material’s properties.

Veryst validated the application by both spring design theory and experiment.

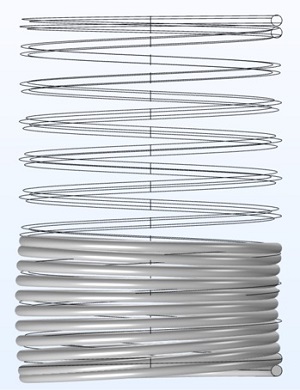

We developed a version of the application for springs with flat ends as well as purely helical springs to validate the model with experimental characterization of manufactured springs. This version simulates contact between the ground ends of the spring to the remaining spring coils to model deformation appropriately. A deformed spring which experiences self-contact before reaching the user-specified failure criteria is shown in Figure 3.

The spring compresses until the stress or expansion levels meet user-specified limits, yield or buckling occurs in the spring, or the spring has reached its solid length.

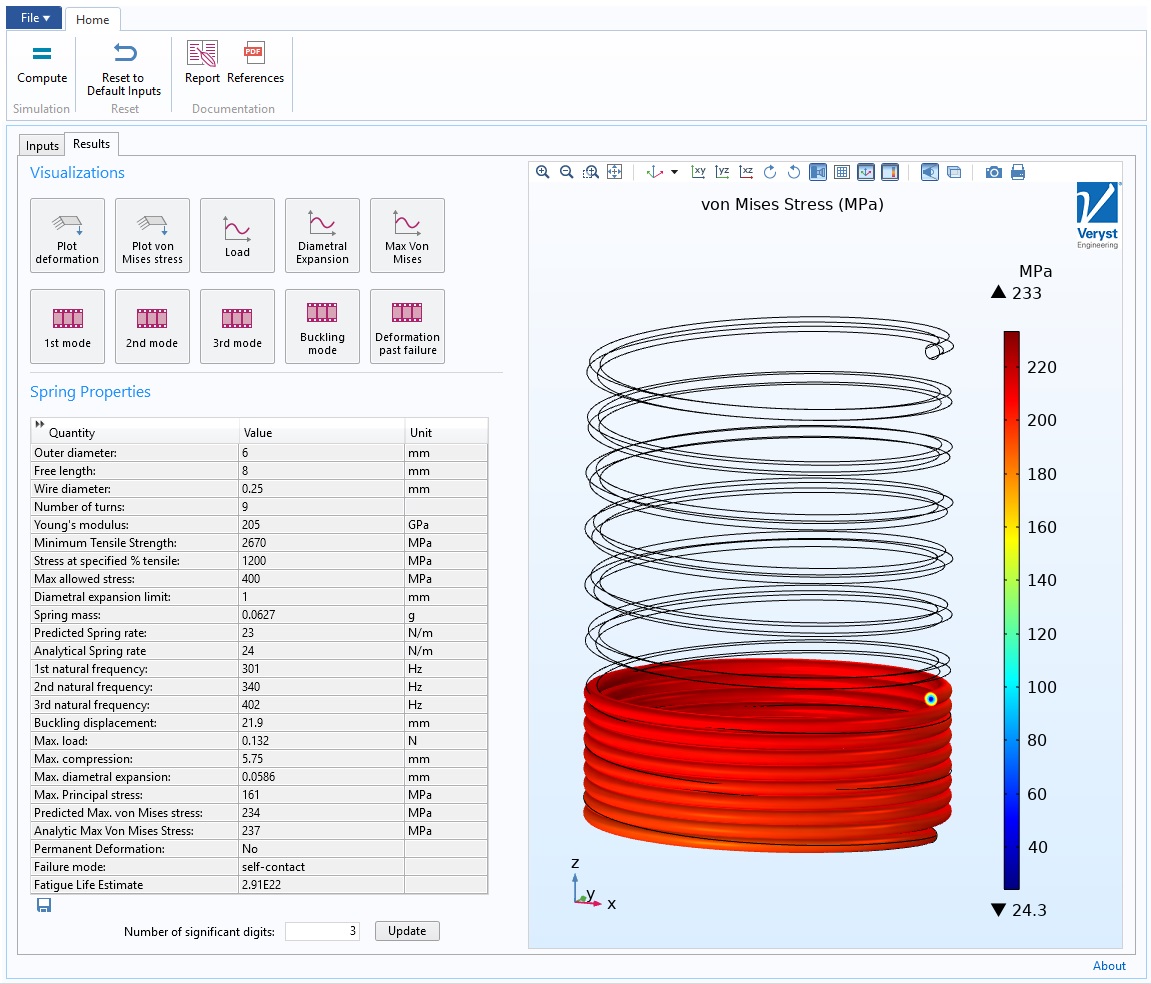

Several important quantities for the spring are displayed including natural frequencies, spring rate, maximum principal stress, and even an estimate of the fatigue life of the spring, as shown in Figure 4.

Figure 5, below, presents a short video demonstrating use of the app.

Conclusion

Veryst’s spring app can be used to characterize the spring rate, buckling modes, maximum stresses, failure modes, and fatigue life estimate for both helical and conical springs. This easy-to-use app enables designers and engineers to perform their own simulations and inform their spring design with validated FEA results.

Learn more about Veryst’s app development services.