Technical Challenge

Vial filling is the high-speed transfer of liquids into tightly regulated containers (vials) via a nozzle. The process is a common step in pharmaceutical and laboratory operations, spanning applications from drug manufacturing to chemical analysis to reagent dispensing. Many application scenarios require the filling process to be exceptionally consistent and reliable, ensuring both product integrity and regulatory compliance. However, filling dynamics are highly sensitive to both physical and operational factors, including nozzle motion, flow ramp

profile, and fluid properties. Even minor deviations can trigger undesirable outcomes such as dripping, jet breakup, splashing, or air entrainment. Achieving robust control over these interactions is essential for designing filling systems that minimize product loss, maximize throughput, and maintain uncompromised quality. In this case study, advanced simulation is used to provide practical guidance for engineers, helping refine filling protocols to ensure reliable production.

Veryst Solution

The computational fluid dynamics (CFD) experts at Veryst developed advanced multiphase flow models to simulate the dynamic filling of a pharmaceutical vial and capture the interplay between interfacial dynamics and nozzle movement. In the simulation, water is introduced through a moving nozzle into a vial initially filled with air. The flow rate is ramped up, held constant, and then ramped down.

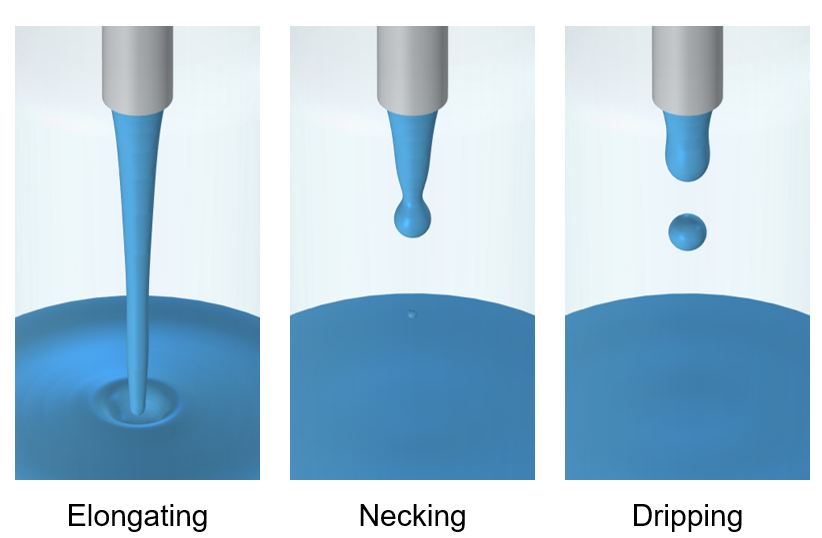

We examined fast and slow ramping. For fast ramping (Figure 1, left), the nozzle remains relatively close to the moving water surface. The higher acceleration and deceleration produce stronger ripples and interface oscillations during filling. In contrast, with slow ramping (Figure 1, right), the interface stays calmer during filling, but during the slow ramp-down, the water jet begins to thin and elongate, eventually leading to undesirable dripping, jet breakup, and splashing (Figure 2).

Conclusion

Using high-fidelity multiphase CFD simulations, Veryst successfully captured the various types of interfacial dynamics that characterize vial filling. By revealing how adjustments to flow rates and ramp profiles influence fill quality, the results provide actionable guidance for optimizing nozzle motion, flow-rate control, and operating conditions to achieve clean, stable fills while minimizing dripping, splashing, and air entrainment. Simulations such as these equip engineers with the insight needed to refine and improve drug manufacturing protocols.