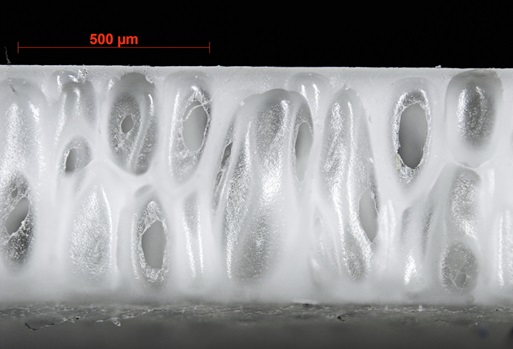

At Veryst Engineering, we understand that highly precise examination is critical to obtaining accurate results; accurate failure analysis and material examination requires the ability to examine even the smallest details. We employ 3D profiling and optical and electron microscopy to capture intricate details of materials that would otherwise be overlooked by visual examination: surface profile and equivalent roughness, contact area, and indications of wear and fatigue.

Optical Microscopy

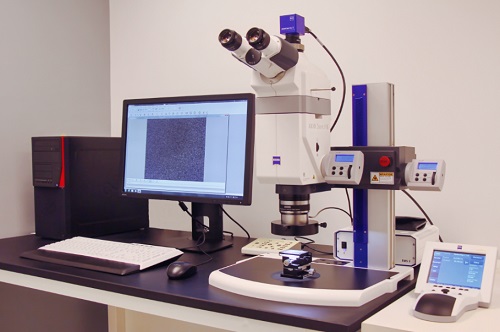

Veryst’s microscopy lab includes a range of different stereo microscopes, digital USB microscope video cameras, and the Carl Zeiss Axio Zoom.V16. This optical microscope is capable of 7x to 112x optical zoom and includes an eZoom option, allowing for automatic positioning of the lenses during zooming to achieve extreme precision. This technology permits Veryst to create images with an extended depth of field which can be used to create topographical, or three-dimensional, images of surfaces or objects, which allows for depth measurements in addition to more traditional in-plane measurements.

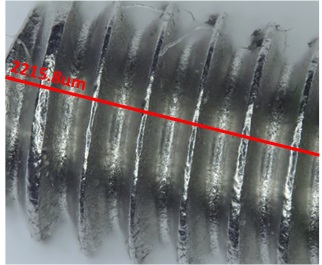

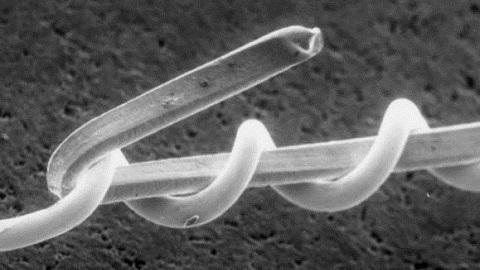

to determine the dimensions of the threads

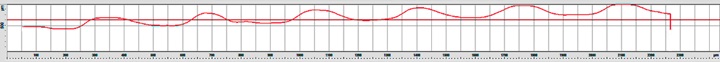

to capture material texture

Scanning Electron Microscopy

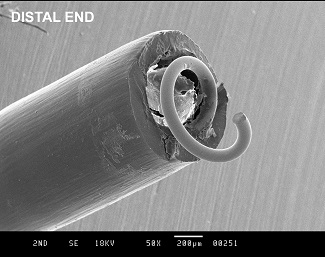

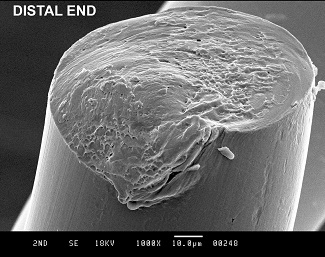

Veryst Engineering employs the use of scanning electron microscopy (SEM) when very high magnification imaging is necessary. Fracture or wear surfaces are commonly examined with SEM for forensic examination. Small features, as commonly found in MEMS devices, adhesive joints, and micro-textured surfaces are also excellent candidates for SEM imaging.

Fig. 4a. Catheter resting on tweezers. Fig. 4b. Distal end magnified 50x. Fig. 4c. Distal end magnified 1000x.