Fourier-transform infrared (FTIR) spectroscopy is a method for identifying the chemistry and structure of a material. FTIR works by measuring the infrared light absorption properties of molecules. Each functional group in a molecule, such as an alcohol or carboxylic acid, absorbs infrared light at different frequencies. Every molecule has a unique fingerprint of infrared absorption bands, and that allows us to identify the different molecules present in a test specimen. FTIR spectroscopy can also measure chemical changes in polymers and plastics, such as degradation, oxidation, or crosslinking.

Veryst measures FTIR spectra with our Bruker Lumos FTIR microscope. FTIR microscopy allows us to make local measurements of FTIR spectra and to map material composition across the geometry of a device. Veryst uses FTIR microscopy for:

- identifying organic materials and chemical impurities for failure analysis and forensic investigations

- analyzing environmental degradation of polymers

- developing and executing accelerated aging protocols

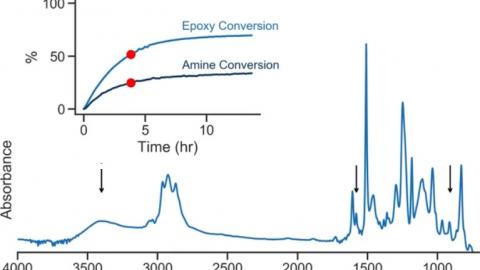

- characterizing curing kinetics of thermal and UV-curing adhesives

- mapping interdiffusion of polymer interfaces

- establishing structure-property relationships in organic materials.

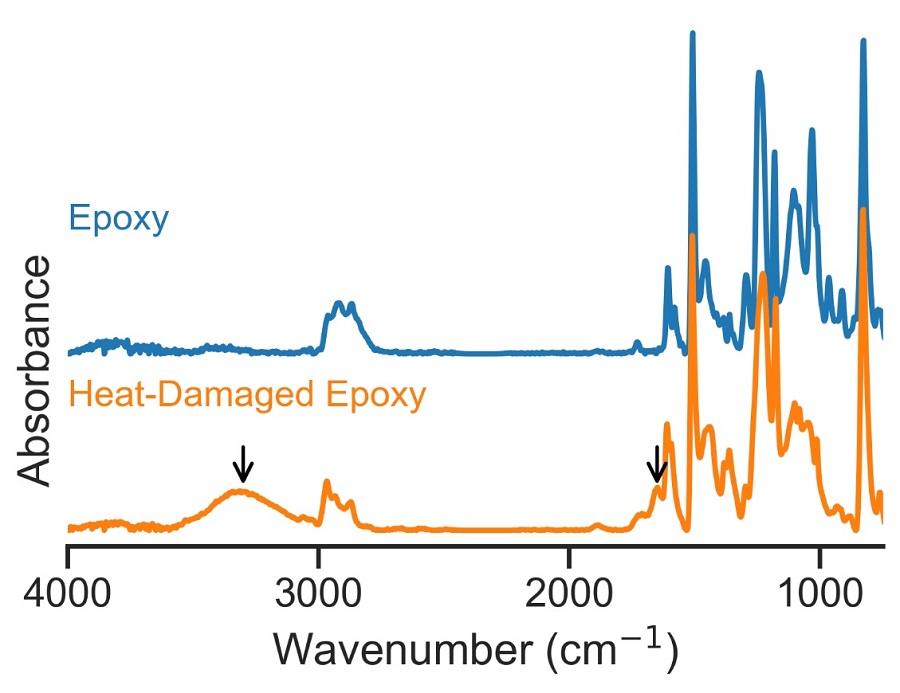

Veryst uses FTIR spectroscopy to identify polymer degradation. In this example, the heat-damaged epoxy has absorbance peaks for alcohols and carbonyls, as indicated by arrows, while the un-damaged epoxy does not. The presence of these peaks demonstrates that the degradation mechanism is oxidation, commonly observed in plastics exposed to heat or corrosive environments.

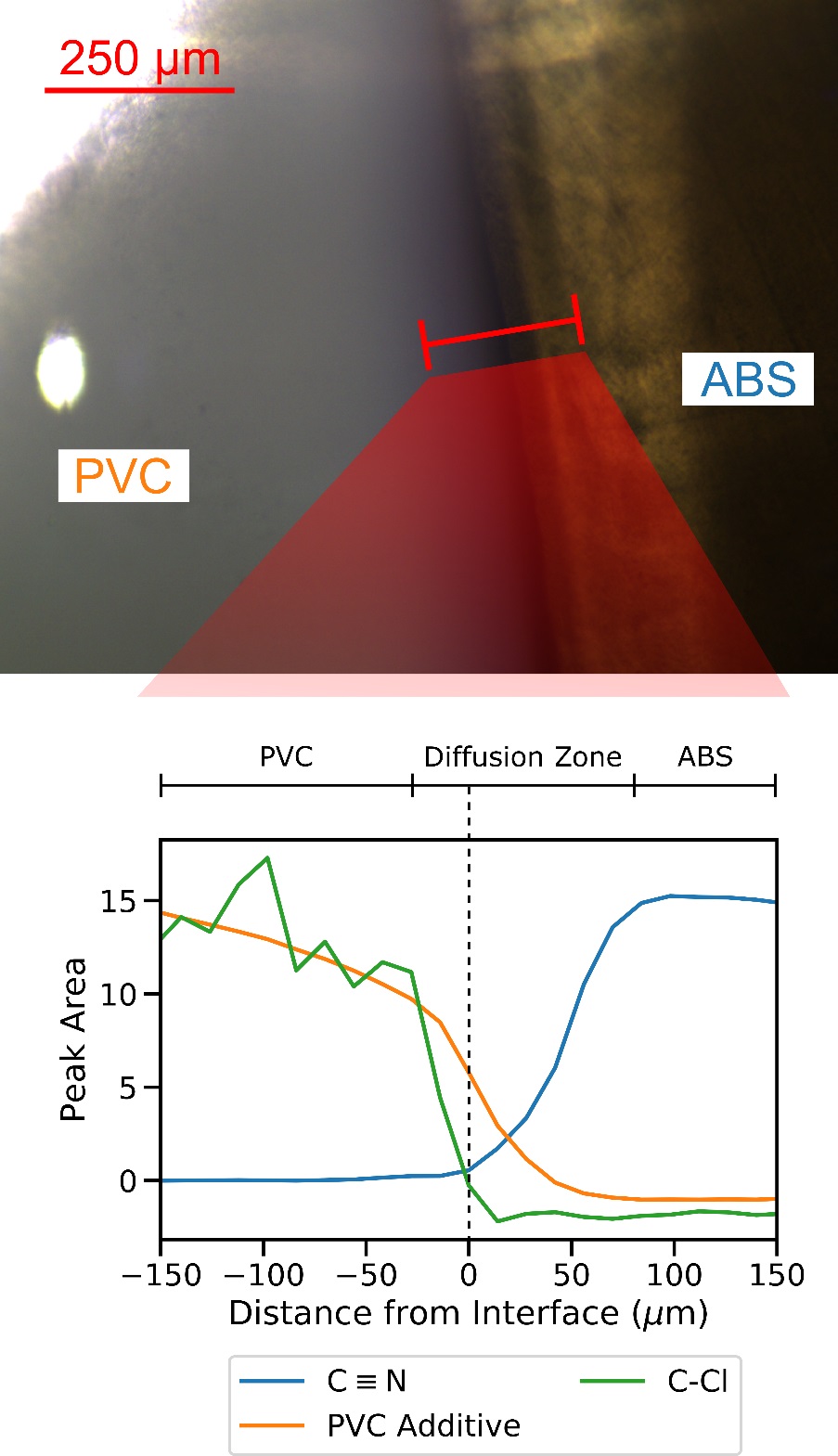

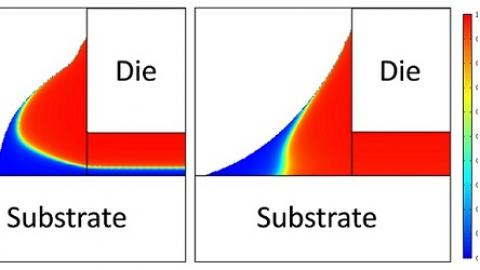

Veryst uses FTIR microscopy to measure material composition with spatial resolution as low as 10 µm.

In this example of a solvent weld between ABS and PVC, Veryst determined that the diffusion zone is primarily on the ABS side of the interface.