Technical Challenge

Rock climbers carefully select their climbing shoes to enhance their climbing performance. The mechanical properties of the outsole rubber, such as its coefficient of friction against the wall or rock, are a crucial design variable that affects climbing performance. Climbing shoe comparisons and preferences are typically anecdotal and rarely quantified when discussed among climbers. Shoe engineers and designers, however, need to understand and compare the mechanical properties of various rubbers to correlate them with climbing performance and to make informed improvements.

Veryst Solution

Veryst performed friction and compression material testing of Vibram XS Edge rubber and ClimbX’s rental shoe rubber. We selected the Vibram XS Edge rubber as it is used in many professional climbing shoes. In contrast, we chose ClimbX rubber from shoes advertised as climbing gym rental shoes. Veryst compared the material properties of these shoes’ rubbers to determine the factors that lead to the superior performance of the Vibram rubber as opposed to the performance of the rental shoe rubber and to quantify the differences between them. The two shoes are shown in Figure 1.

Friction Testing

Veryst tested both rubbers in friction tests under various conditions and between two substrates of different surface roughness: a rough wood panel to replicate a climbing gym wall and a granite stone to replicate a rock wall. We cut square flat samples from the rubber outsole and tested the samples using our custom friction testing fixture.

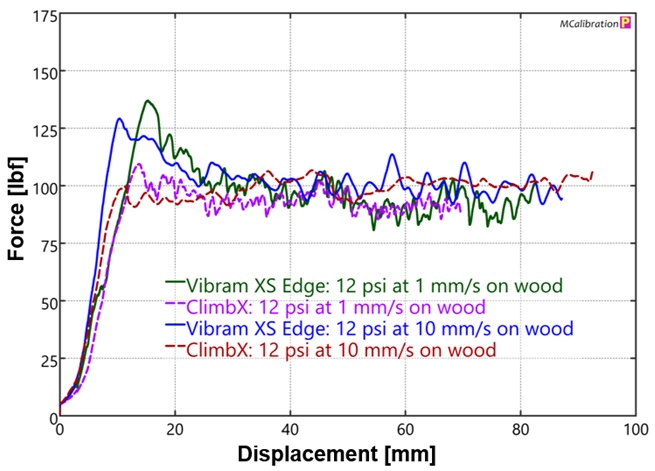

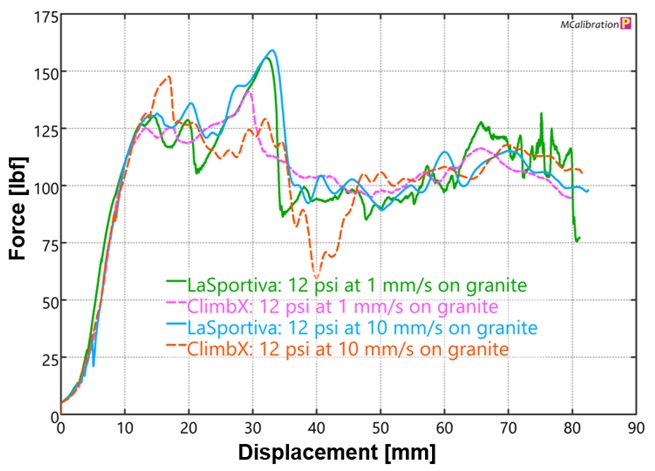

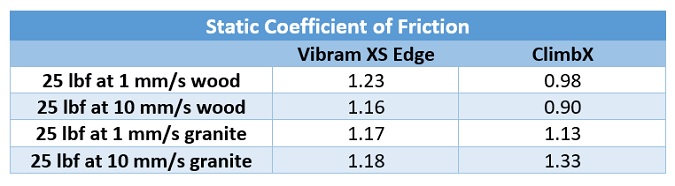

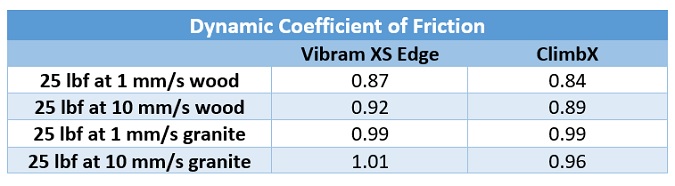

We tested the rubber samples at two displacement rates, 1 mm/s and 10 mm/s, and one normal pressure, 12 psi. The friction test results are shown in Figure 2. The test results show that the Vibram XS Edge rubber has a higher coefficient of friction, particularly on the lower friction wood surface.

Figure 2. Friction test results of Vibram XS Edge rubber and ClimbX rubber.

Uniaxial Cyclic Compression Testing

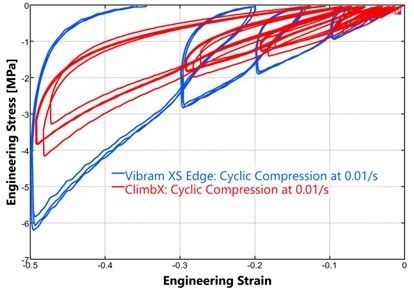

Veryst also performed uniaxial cyclic compression tests with 30 second stress relaxation holds to analyze and compare the material properties of the rubbers, particularly their stiffness and viscoelasticity.

We die-cut cylindrical samples from flat sections of each outsole and tested three repeats of each material at a strain rate of 0.01/s. The compression test results are shown in Figure 3. The Vibram material shows a stiffer response as well as more hysteresis during unloading.

Material Model Calibration

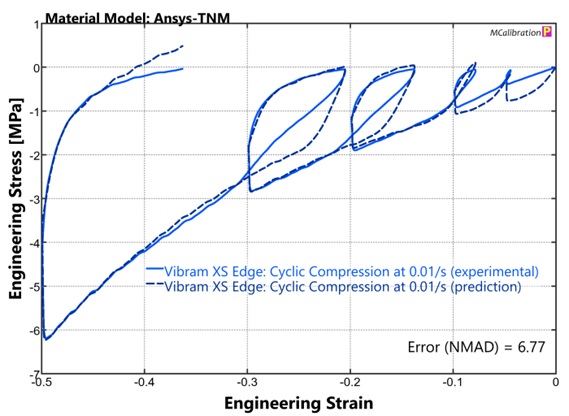

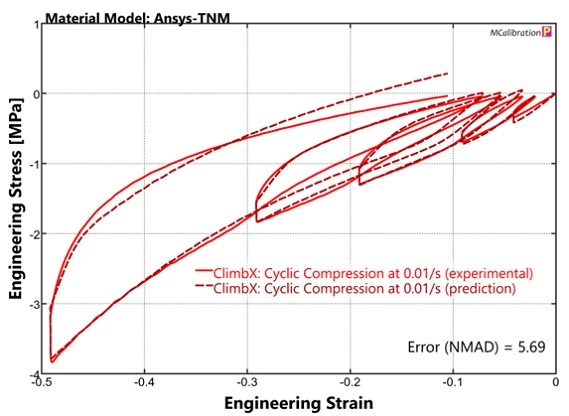

Veryst calibrated an ANSYS Three Network Model (TNM) to the compression data of each rubber material. TNM is an advanced material model for simulating most polymer materials and is well-suited for modeling both rubber materials.

The calibrated Three Network Models accurately capture the response of each material. The experimental results and model predictions are shown in Figure 4 for a representative curve of each material. These models can accurately capture the material response using finite element analysis (FEA).

Figure 4. ANSYS Three Network Model (TNM) calibrated to the data of both rubbers.

Comparison

The two rubber materials have clear differences in friction properties. On wooden panels, the Vibram XS Edge rubber has a larger static coefficient of friction. For climbers, this translates to the shoe being less likely to slip against a climbing gym wall. However, the difference in coefficient of friction is indistinguishable on the granite substrate. The two climbing shoes will have varying friction performances depending on the substrate on which they are used. The two rubber materials should also be tested against plastic climbing hold samples to assess and compare their performance in a climbing gym where rental shoes are typically used. Assessing outdoor performance has an additional challenge as outdoor rock composition and roughness will vary.

The two rubbers also have drastically different properties under compressive and stress relaxation loading. The Vibram XS Edge rubber stiffens faster with increased compressive strain and experiences a larger amount of stress relaxation. This property indicates that the Vibram XS Edge rubber will experience a larger amount of creep under a set load, such as a climber's static weight, further increasing the friction surface against the climbing surface. Additionally, an outsole’s stiffness will change the shoe’s comfort and sensitivity feedback for a climber.

Further Testing

Climbing shoes experience a complex range of loading conditions. Further testing is required to provide a complete look into each shoe rubber’s performance. Veryst would recommend performing friction tests with the actual wooden panels, plastic holds, or types of rocks against which the shoes are used. We would also explore a larger range of normal forces representative of climbers wearing the shoes. This range of forces will depend on climber weight and amount of force they exert with their foot on the wall. Lastly, Veryst would recommend characterizing the material at a variety of temperatures and humidities—as would be experienced outdoors—to determine how to improve outdoor climbing performance.