Technical Challenge

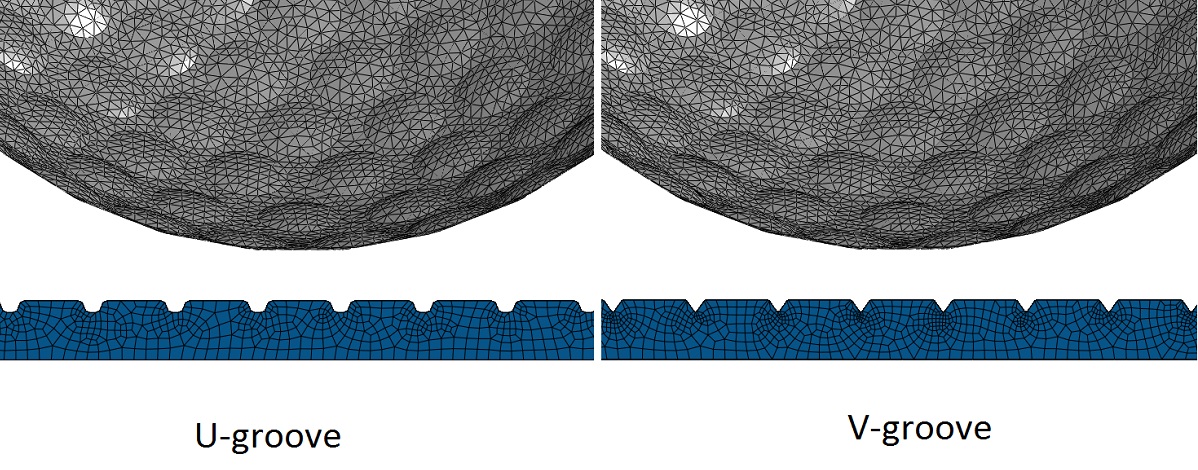

The United States Golf Association sets certification criteria of golf balls and club faces (i.e. groove geometries) based on measured characteristics of the ball’s impact response, such as velocity and spin rate. Ball and club designers attempt to “tune” these characteristics for improved performance within these guidelines.

There is a need for accurate, predictive simulations to understand how changes in material response and geometry of the ball and/or club face can affect these variables.

Veryst Solution

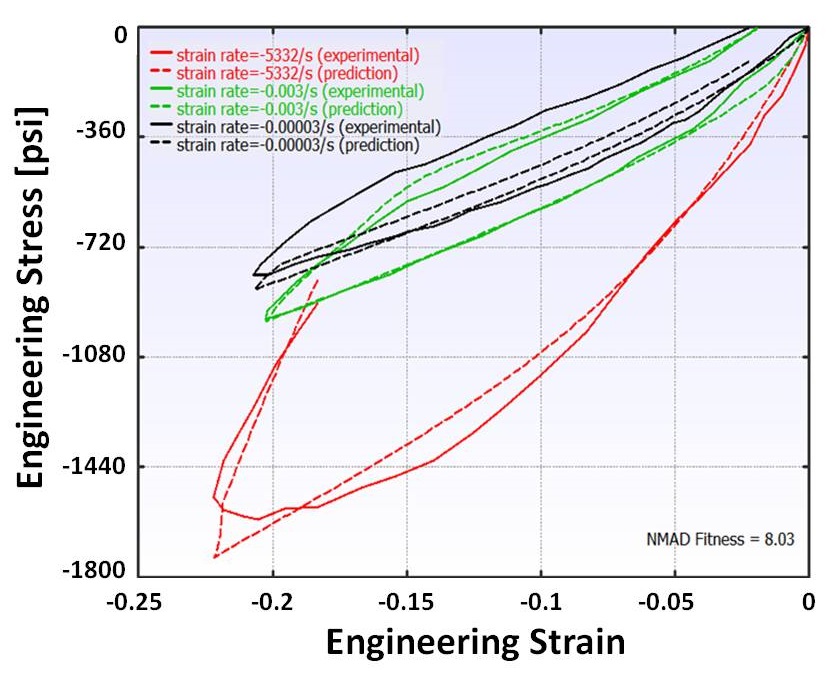

Veryst has extensive experience modeling nonlinear, dynamic events. Here, an advanced constitutive model from the PolyUmod® library was calibrated to high-strain rate experimental data (over 5000 1/sec) for golf ball materials using MCalibration®, both programs developed by Veryst and now available through PolymerFEM.com.

Veryst created a three-dimensional, explicit finite element simulation to model club face impact with a ball. The model is created using a scripting language (Python), allowing for parametric studies of changes in material and ball and/or club-face geometry to understand the effect on response parameters such as impact velocity and spin rate.

For standard groove geometries, ball materials, and incident velocities, Veryst’s simulations show good agreement with data gathered by the USGA. Parametric studies may be used to shorten the design cycle by optimizing targeted properties and/or geometries in the design of a club or a ball. Veryst’s work demonstrates a clear need for use of an advanced constitutive theory for golf ball materials as well as experimental data at high strain rate in order to get the most accurate predictions.