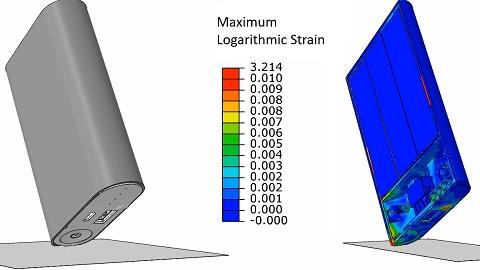

Structural finite element analysis (FEA) enables engineers to calculate the deformation, stresses, and strains that develop within their products when subjected to real-world load cases and predict how the product will perform. FEA is an invaluable tool for guiding mechanical design, material selection, and manufacturing decisions as well as for understanding prototype and product failures. FEA can save significant product development time and budget--when used well.

Many firms offer FEA services, but companies around the world and from all industries come to Veryst. Why?

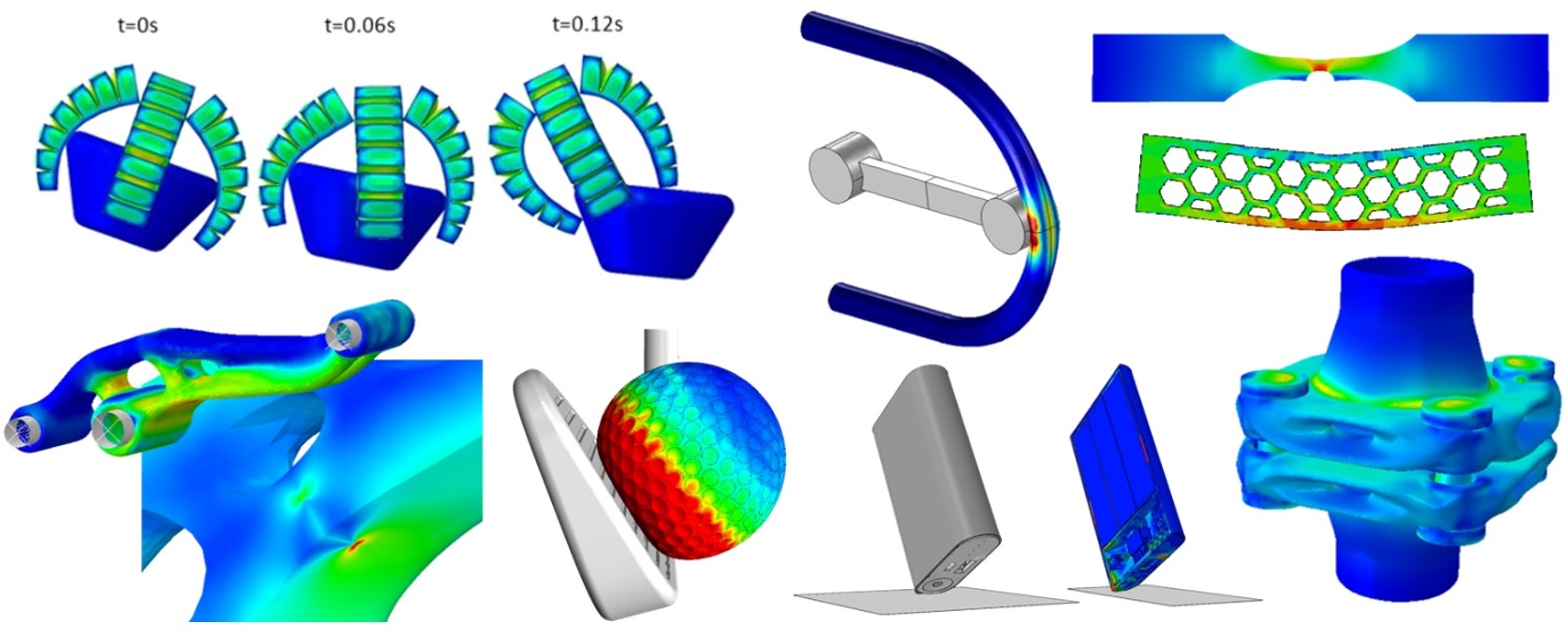

1. We Specialize in Complex, Nonlinear Problems

We specialize in analyzing difficult problems that involve one or more of the following characteristics that make problems nonlinear and difficult:

Polymeric Materials

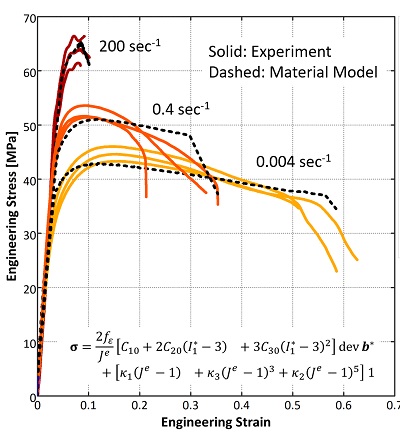

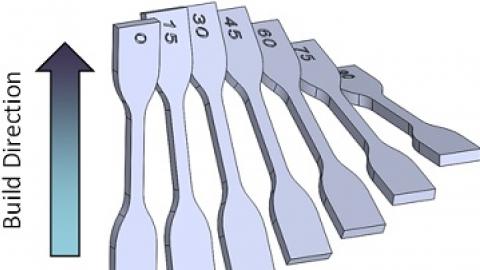

Veryst has expertise in modeling polymeric materials that exhibit nonlinear, rate- and temperature-dependent behavior. We can model parts made of foam, thermoplastics, thermosets, composites, elastomers and rubbers, adhesives, biomaterials, and other non-linear materials.

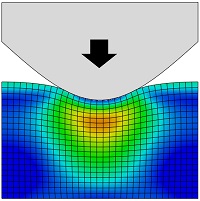

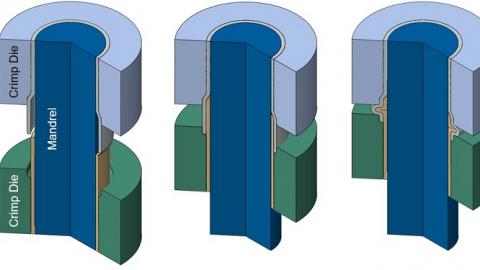

Contact

Veryst has expertise in solving problems involving contact between parts in an assembly. This includes multiphysics problems where contact conditions influence the thermal, acoustic, electromagnetic, and/or fluid flow fields.

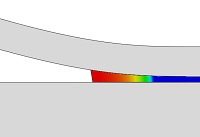

Debonding of Interfaces and Adhesives

Veryst has expertise in modeling interfacial delamination in multilayer assemblies and failure of adhesive joints. We can model all classes of adhesives ranging from soft PSAs to highly-crosslinked thermosets.

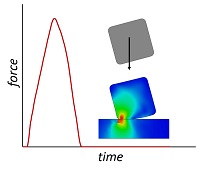

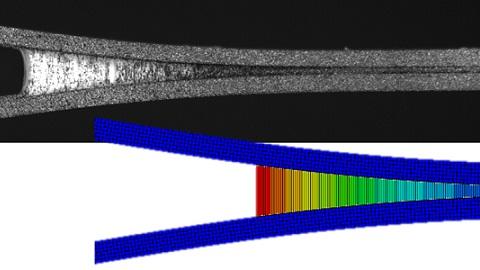

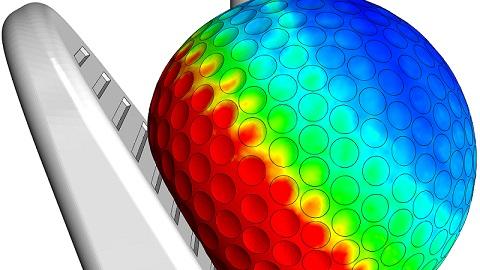

Impact Loading

Veryst has expertise in both dynamic implicit and dynamic explicit analysis. We specialize in problems that involve such complexities as contact, rate-dependent material models, and material failure.

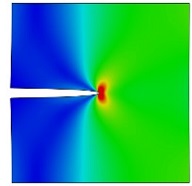

Material Failure

Veryst has expertise in modeling material failure of engineering materials. We use approaches such as elastic-plastic fracture mechanics, cohesive zone modeling, and dynamic explicit simulations with element deletion.

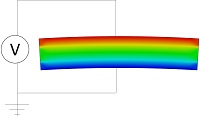

Coupled Physics

Veryst has expertise in solving multiphysics problems involving structural mechanics. Examples include fluid-structure interactions and coupled electro-thermo-mechanical problems.

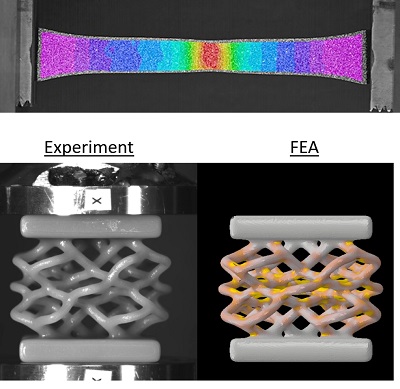

2. We Have an In-House Material and Validation Testing Lab

Veryst has a 3000 square-foot mechanical testing lab equipped with universal test frames, environmental chambers, a DMA (dynamic mechanical analyzer), and custom-built equipment for high-rate testing. We can measure mechanical properties of materials relevant to most structural analyses. We can also run validation experiments to quantify the accuracy of our analyses. When we conduct a project with both a testing and FEA component, our experimental and computational engineers work closely together to ensure the most accurate results possible within the project budget.

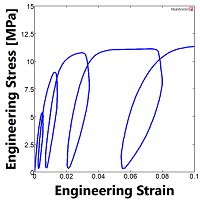

3. We Are Experts in Calibrating and Using Advanced Material Models

In many finite element simulations, the most challenging step is the definition of an appropriate material model that captures the experimentally observed nonlinear response of the material. Calibrating these models requires both high-quality experimental data at the strain magnitudes, strain rates, and temperatures relevant to the application and expertise in calibrating constitutive models to that data. We can calibrate models that capture time and temperature dependance, anisotropy, and failure of a wide variety of materials.

Working with Veryst

There are several phases to a successful FEA project:

Project Scoping and Proposal

We work with our clients to understand how FEA will inform the engineering decisions they are trying to make to ensure we analyze the right variables and model the problem with the appropriate level of detail, all while being mindful of the client budget. We are not tied to using one software package and can use the software best suited to any given problem. Our engineers have expertise in using the advanced features of Abaqus, ANSYS Mechanical, LS-DYNA, and COMSOL Multiphysics. Once we have assessed the scope of the project, Veryst will provide a written proposal that clearly outlines how we will work together to improve your design.

Material Testing and Model Calibration

Data available on material technical data sheets are often insufficient to model accurately the material behavior using FEA. Therefore, in many cases we start an FEA project by first experimentally measuring the mechanical response of the materials used in the part/assembly and calibrating a material model for those materials.

CAD Defeaturing

Veryst has expertise in defeaturing solid models of parts and assemblies to optimize the geometry for finite element analysis. We work with clients to decide where we can make appropriate simplifications to the model to reduce computational time and where we need to maintain high model fidelity.

Model Development

We meet regularly with clients while we are completing our analyses to update them on project status, discuss modeling assumptions, share preliminary results, and update the model based on client feedback.

Reporting

Veryst not only delivers clear descriptions of simulation methods and results but provides interpretation and recommendations to assist clients with making the best engineering decisions they can.

Model Delivery

Models developed by Veryst belong to our clients. We will share all simulation files, if desired, for internal client use.