Technical Challenge

Many engineering applications use foams for their impact-absorbing properties. While foams have a low stiffness at low strains and strain rates, the structural compaction they experience when compressed often leads to a significant stiffness increase at high compressive strains. In addition, foam material properties are often very strain rate dependent.

Engineers need to characterize their foams at high strains and a range of strain rates to model the material accurately using finite element analysis (FEA) and make informed decisions for material selection. These testing requirements can be difficult to achieve with standard test machines due to the complexities of measuring the full range of forces and low displacements at high displacement rates.

Veryst Solution

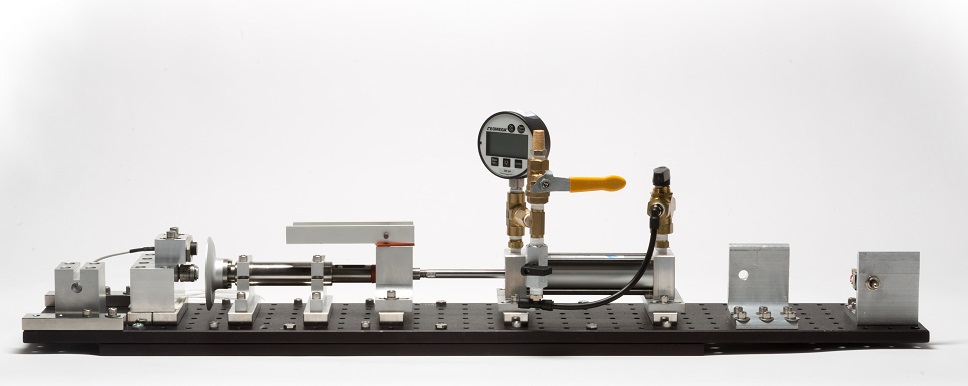

Veryst Engineering developed a custom-built thin film and adhesive test machine to measure the low and high rate properties of thin samples. The test machine is capable of accurately measuring foam materials under impact conditions and can test samples that are as thin as 50 μm and as thick as 5 mm in tension, compression, and shear.

The test machine is shown in Figure 1.

Utilizing our custom thin film test machine, Veryst performed moderate and high rate material testing on a thin foam material used in consumer electronics. We die-cut cylindrical samples, 6.35 mm in diameter and 1.5 mm thick, from a foam sheet and ran compression tests on these samples at a range of strain rates, reaching impact strain rates over -1500/s. A video of a high rate compression test is shown in Figure 2, captured with a high speed camera at 10,000 fps.

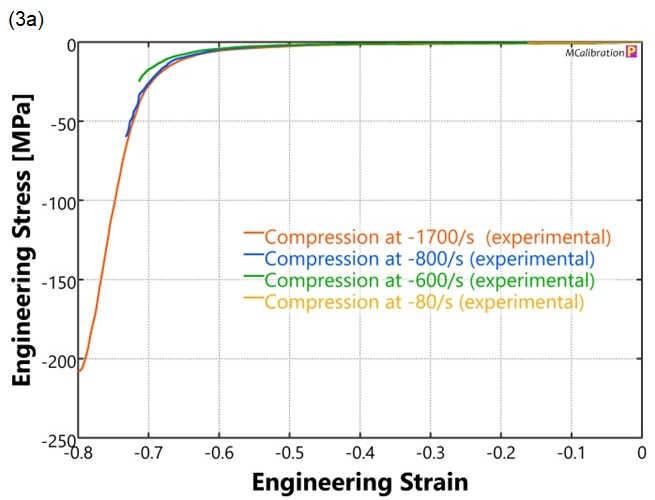

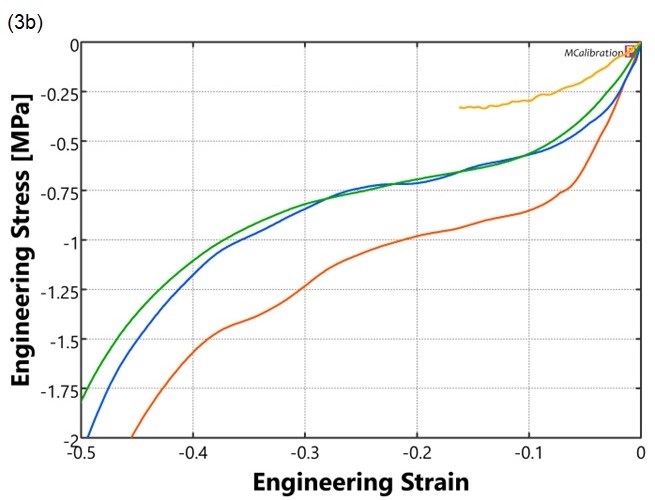

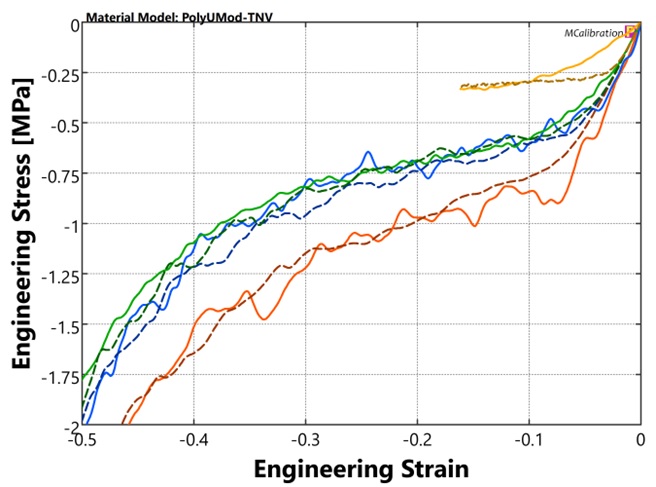

Veryst measured the compressive response of the foam material at four strain rates. The material shows a moderate strain rate dependence at these strain rates. Both the stiffness and yield stress of the material increase with strain rate. The test results are shown in Figure 3.

Figure 3. Test results of the foam. Figure 3a shows stress and strain curves at four strain rates. Figure 3b presents the same results as in 3a, but shows representative curves at each rate at lower strains.

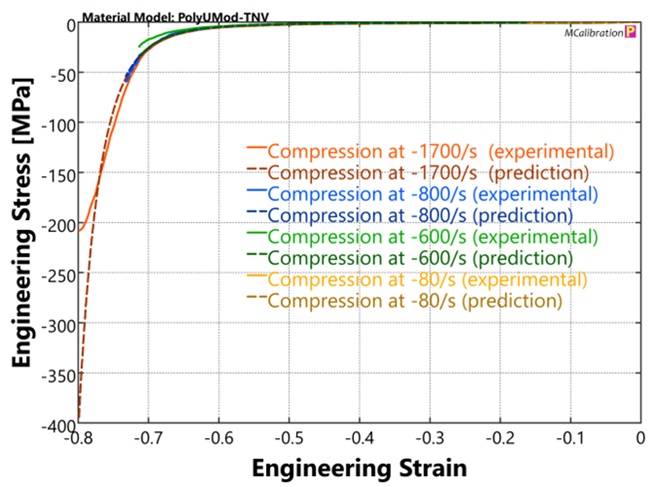

Veryst calibrated a PolyUMod® Three Network Viscoplastic (TNV) material model for the foam material for use in ANSYS, Abaqus, LS-DYNA, COMSOL, RADIOSS, or Marc. The TNV model is an advanced material model for capturing the viscoplastic response of most polymers and can accurately measure the foam’s strain rate dependent response at the full strain range.

The TNV model uses parallel networks of nonlinear springs and dashpots. This model includes two hyperfoam springs and one pressure-dependent power-law flow element. The model can accurately capture the moderate and high rate response of the foam material, as shown in Figure 4.

Figure 4. PolyUMod Three Network Viscoelastic (TNV) model calibrated to the foam data.

The foam material exhibits typical behavior for foams designed for impact mitigation – the foam stiffens significantly due to compaction at high compressive strains and shows a high rate dependence over a moderate strain-rate range. The material model is ready to be used to predict product performance and optimize the design to survive impact events.

Veryst can also further customize the model by testing the foam in shear and tension at equally high strain rates using the thin film test machine, or at quasi-static rates using our electromechanical test machines. We work with clients to develop test plans and calibrate material models that accurately capture the behavior of their material.