Material model selection and calibration for finite element (FE) simulations typically utilize uniaxial test data. Veryst recommends validating the material model to ensure that the model accurately captures multiaxial load cases. Typical validations tests such as indentation testing or small punch tests are performed at quasi-static rates even when the application is an impact event.

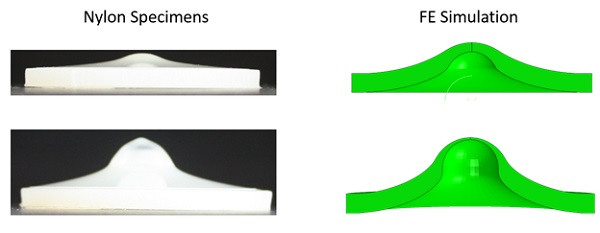

Veryst has developed a high strain rate punch test to validate material models in biaxial loading. A hemispherical indenter impacts a disk at velocities from 100 mm/s to 5000 mm/s, typically deforming the specimen to failure. Displacement of the impact head is measured using a high speed video camera and Digital Image Correlation (DIC), while force is measured throughout the experiment. We perform a finite element simulation with the candidate material model and compare the force-displacement results of the simulation to the experiment.

For a customized quotation, please write to us at testing@veryst.com.