Dynamic mechanical analysis (DMA) testing is a straightforward way to characterize materials in small-strain regimes. DMA is useful for characterizing polymer:

- Temperature dependence

- Glass transition temperature (Tg)

- Frequency dependence

- Creep and stress relaxation

Veryst uses DMA testing to characterize the viscoelastic response of materials over a wide range of temperatures and frequencies. The complex viscoelastic modulus of the material is determined by applying a sinusoidal stress or strain history. This test is repeated over a wide range of temperatures, frequencies, or strain amplitudes, yielding valuable information that can be used in MCalibration® to select and calibrate a material model for finite element analysis.

Time-temperature superposition (TTS) enables viscoelastic material properties to be calculated at high frequencies (>10,000 Hz). Samples tested at low temperatures behave similarly to materials tested at high frequencies and rates. By testing polymers over a wide range of temperatures and frequencies, a master curve can be used to determine the viscoelastic behavior at frequencies higher than the applied test frequencies.

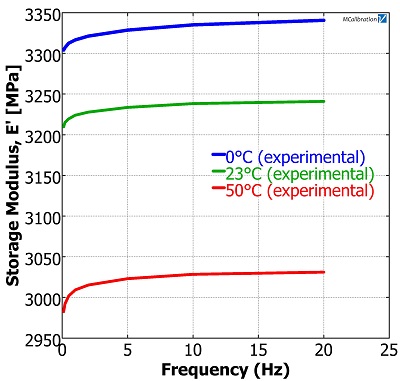

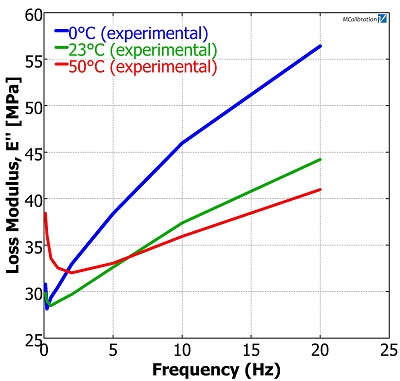

Veryst’s test machine (TA Instruments Q800, shown above) has test fixtures for tension, compression, shear, and cantilever bending, allowing us to test materials from soft foams and hydrogels to stiff thermoplastics. The graphs below show representative results for the storage and loss modulus of a stiff thermoplastic sample tested at multiple temperatures and frequencies, highlighting the change in material properties with applied temperature and frequency.

Storage modulus measured at three different temperatures and multiple frequencies for a thermoplastic. Over this narrow range of temperatures, the storage modulus increases by 10%. Additionally, the storage modulus increases with applied frequency.

Loss modulus measured at three different temperatures and multiple frequencies for a thermoplastic. Over this narrow range of temperatures, the storage modulus increases by 30%. Additionally, the loss modulus increases with applied frequency.

For a customized quotation, please write to us at testing@veryst.com.