Engineering materials are typically tested in a straightforward manner, measuring the uniaxial state of stress. In many cases it can be useful to validate that a calibrated material model accurately captures the response in a multiaxial loading mode. One effective way to examine the high rate compressive response is to use an instrumented ball impact test system.

Veryst designed and uses an instrumented ball impact test to create a multiaxial compressive stress state with an effective strain rate that can exceed 10,000/s.

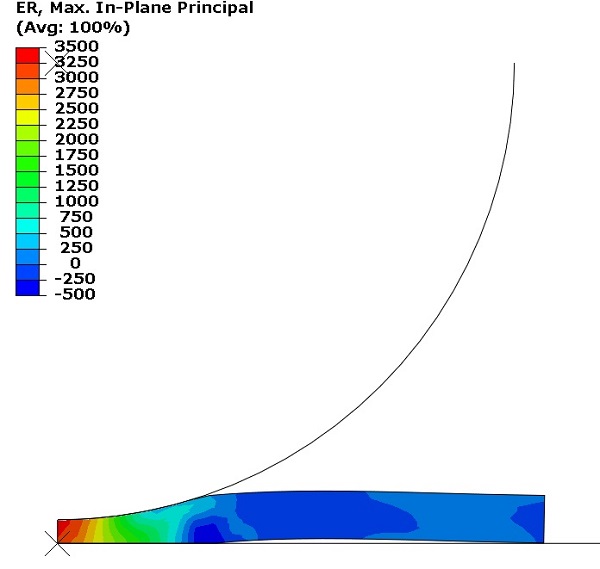

The instrumented ball impact test, shown below, is designed to measure the viscoplastic response of a material. In the test, a stiff sphere (typically steel) of known mass and diameter is dropped from a known height onto a sample of the material. Force is measured underneath the sample and the experiment is simulated in finite element (FE) software. The results are used to validate a material model calibrated with uniaxial data and can be used to determine the amount of energy absorbed. The test results can also be used to calibrate a suitable material model using an inverse FE approach.

For a customized quotation, please write to us at testing@veryst.com.