Veryst engineers have broad expertise in the material science and mechanics of adhesive joints and bonded interfaces. We use this expertise to help clients design robust adhesively bonded structures and to understand delamination failures. Veryst offers a full suite of engineering services, including mechanical testing, cohesive zone model calibration, finite element analysis, and bonding process simulation.

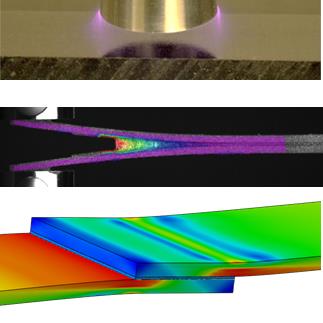

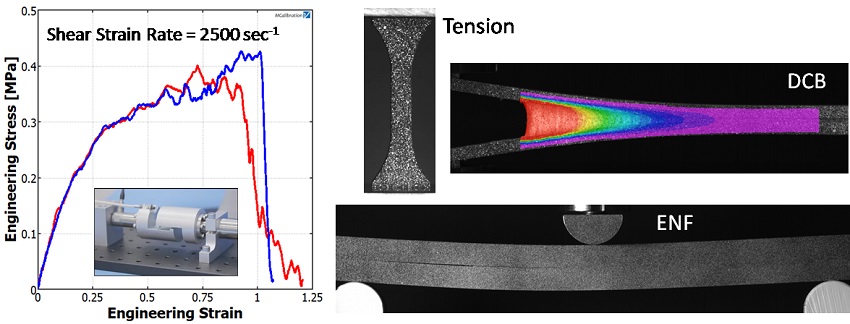

Mechanical Testing

Veryst offers mechanical testing services to characterize the strength and toughness of adhesive joints, composite laminates, and material interfaces. As adhesive strength and toughness can depend upon many factors (interface geometry, loading type, environmental conditions, etc.), we work with clients to design and implement customized testing procedures that expose adhesive joints and interfaces to in-service conditions.

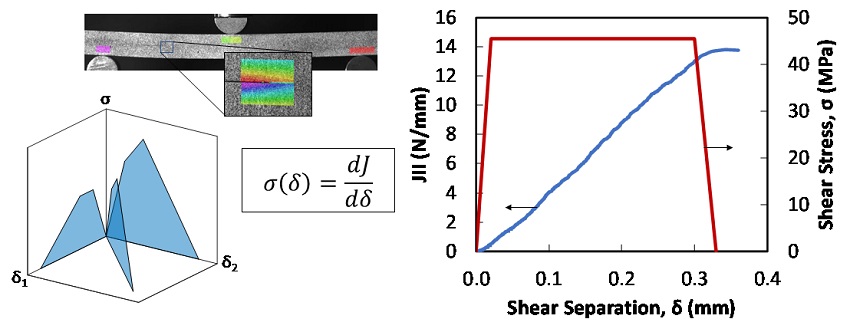

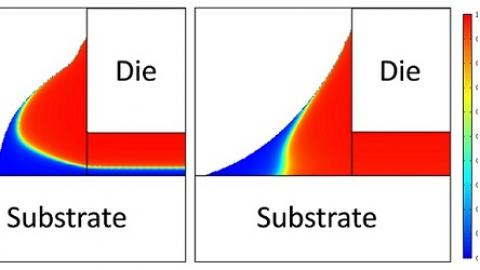

Cohesive Zone Model (CZM) Calibration

Veryst Engineering experimentally measures the traction-separation behavior of adhesives for calibration of cohesive zone models. We have calibrated models for both soft and rigid adhesives for applications in industries such as biomedical, electronics, and automotive. We calibrate models for use in Abaqus, ANSYS, COMSOL Multiphysics, and LS-DYNA.

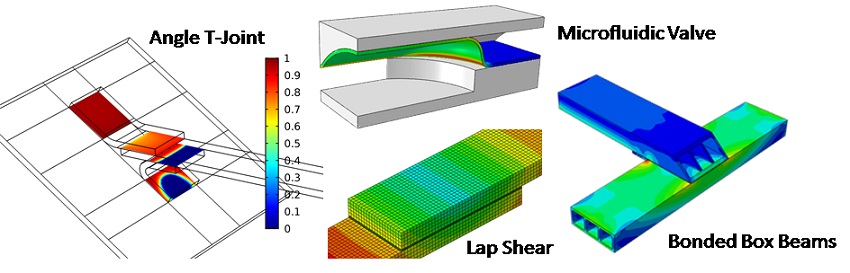

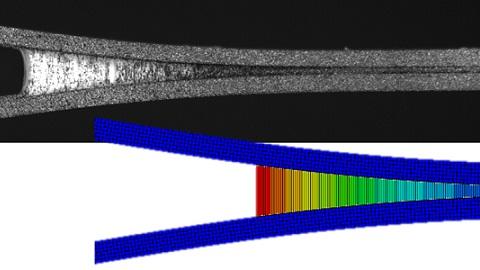

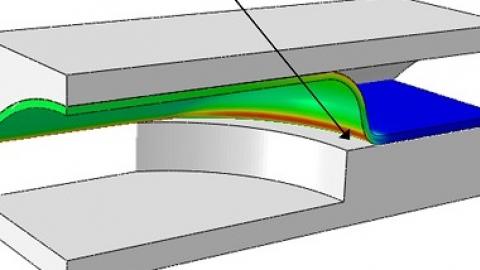

Finite Element Analysis

Veryst Engineering conducts stress and fracture mechanics analyses to help clients design robust structures and understand failures. Veryst is a world-leader in finite element modeling of polymeric materials, including adhesives.

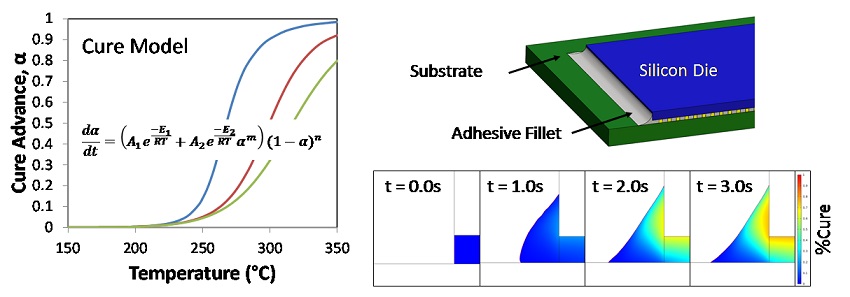

Bonding Process Simulation

Advanced adhesive joining processes are inherently multiphysics in nature, involving curing of the adhesive, heat transfer through complex structures, and flow behavior that depends upon the temperature, flow rate, and degree of cure of the adhesive. Veryst has extensive experience with multiphysics modeling involving fluid flow, fluid-structure interactions, heat transfer, and chemical reactions.

Fourier-Transform Infrared (FTIR) Spectroscopy

Optimizing the performance of an adhesive joint requires a thorough understanding of the curing process of the adhesive. Veryst uses FTIR spectroscopy to analyze the chemistry of the curing process of adhesives, tracking real-time concentrations of the reactive species to gain a comprehensive understanding of the cure process. In addition, we can investigate the location-dependent material chemistry of a bonded interface with our FTIR microscope, which can measure FTIR spectra at a spatial resolution of 10 µm.