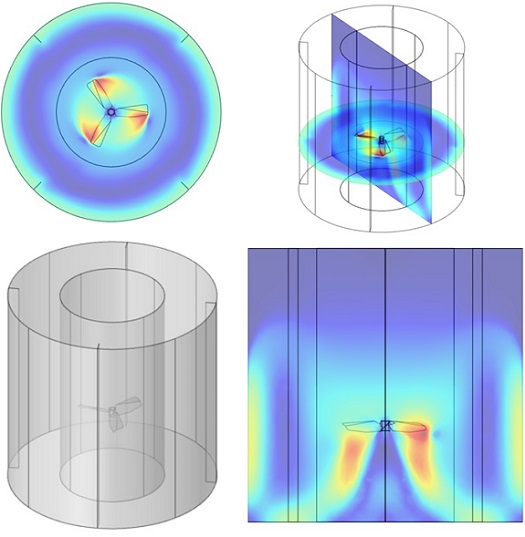

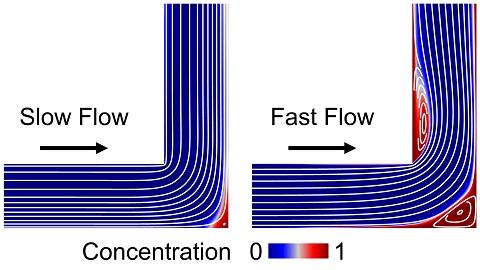

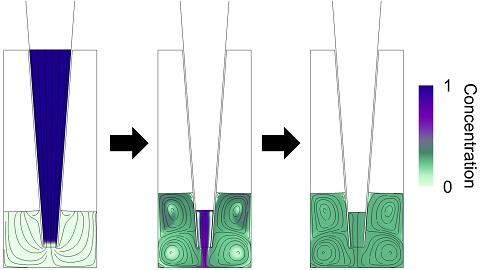

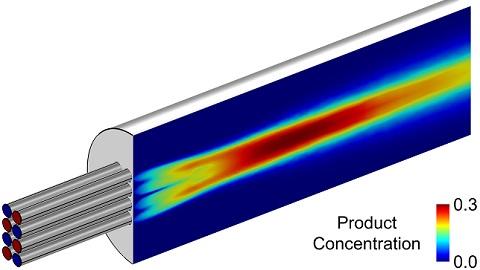

Veryst assists clients in solving challenging problems involving chemical reactors and bioreactors. We employ advanced simulation and multiphysics tools in addition to analytical models to address the many layers of coupled physics – fluid flow, heat transfer, chemical reactions, thermodynamics, and porous media – that are often involved in reacting systems. Our engineers have applied their deep understanding of these underlying physical phenomena in applications such as reactor scale-up, focusing on the associated changes in the rates of relevant transport processes, distributor manifold design, and prediction of mass transfer in multiphase systems.

Expertise

- Laminar and turbulent flow

- Multiphase flow

- Heat transfer

- Mass transfer

- Flow in porous media

- Colloids and particulate flows

- Chemical reactions

Applications

- Biotechnology

- Pharmaceutical

- Batteries

- Consumer products

- Food products

Veryst Capabilities

- Reactor scale-up

- Multiphase flows (droplets, bubbles)

- Microfluidic reactors

- Lab-on-chip devices