Veryst has deep expertise in fluidic mixing processes, which we leverage for our clients across industries. A fundamental aspect of mixing is the stretching and folding of the interface between initially separated substances. This occurs in many forms and systems: agitated versus static mixers, laminar versus turbulent flows, lab versus production scale, etc. It also occurs in systems where mixing is weakly coupled with the flow (passive mixing) or tightly coupled with the flow (mixing of variable density substances, flows with chemical reactions, multiple phases, etc.).

Veryst’s consultants employ advanced computational fluid dynamics (CFD) tools and analytical models to understand and visualize complex flow behavior. We use our grounded knowledge of computational methods, fluid mechanics, and physics to provide practical design recommendations. Clients use our analyses to understand and improve mixing performance and to scale-up or down between lab, pilot and production scale systems.

Microfluidic and Laminar Mixing

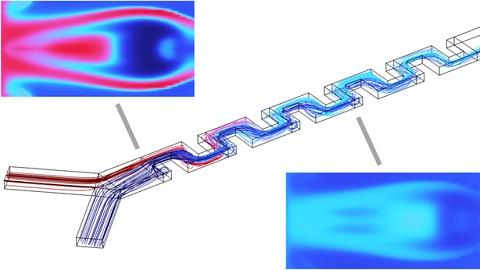

that generates recirculation to promote fluid mixing.

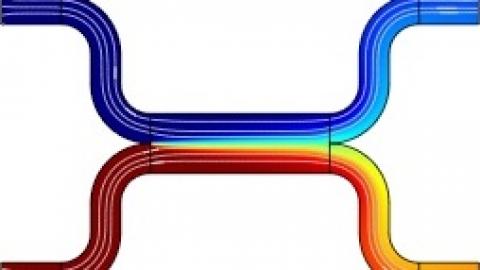

Mixing input streams is a key step in microfluidic and laminar flow systems such as flow cells in DNA sequencing, small-batch mRNA vaccine production, and lateral flow, wearable, or point-of-care diagnostic tests.

A key design challenge of microfluidic and laminar fluidic systems is how to mix reagents rapidly, effectively, and efficiently. Unfortunately, the efficient turbulent mixing available to larger scale flows is generally not available for microfluidic and laminar systems. Moreover, even though microfluidic devices have channels with small dimensions, the diffusive mixing occurring within is still generally far too slow and inefficient. Additional challenges for these systems include efficient use of reagents and developing designs that can be manufactured repeatably, reliably, and cost-effectively.

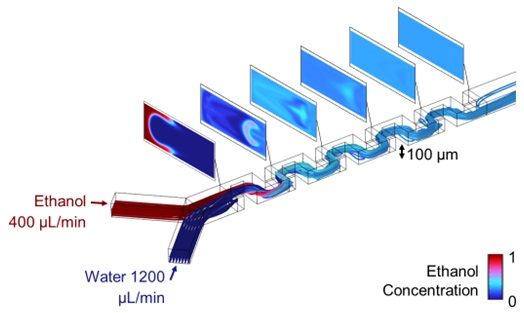

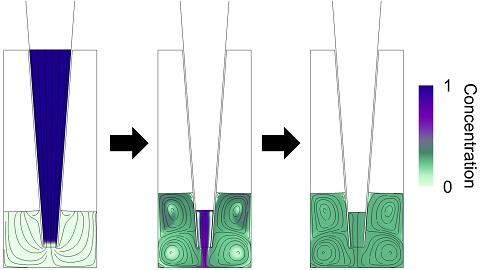

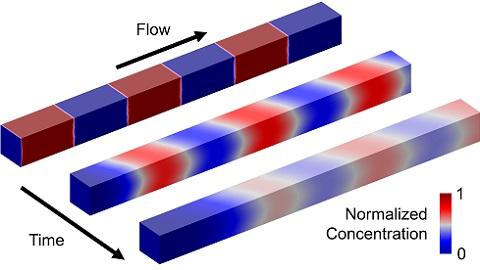

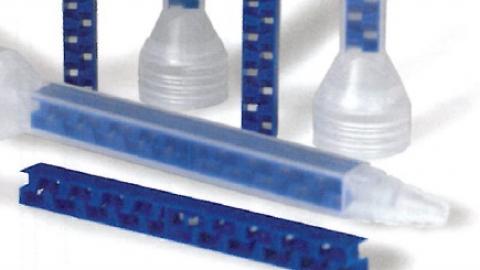

Effective and efficient mixing in microfluidic and laminar systems may be accomplished passively via geometrical features such as serpentine channels (see figure) or active methods such as asymmetric wall motion or agitation. We explore and compare passive chaotic mixing via serpentines, rings, and herringbone grooves in an instructive case study.

Turbulent Mixing

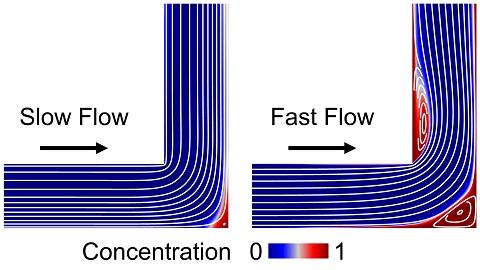

Turbulent mixing systems leverage the eddies and fluctuations that arise from the chaotic nature of such flows to stretch and fold the interfacial areas between the substances being mixed. In a typical mixer, large eddies are created either by mechanical agitation or shear (e.g., a jet into a quiescent medium). These eddies disperse and break into smaller and smaller flow scales. This process stretches, folds, and engulfs pockets of unmixed fluid to create more interfacial surface area and to promote diffusion. Mixing in turbulent flows is typically characterized by the Reynolds, Schmidt, and Damköhler numbers, which quantify the importance of inertial forces, momentum diffusion, and chemical time scales, respectively.

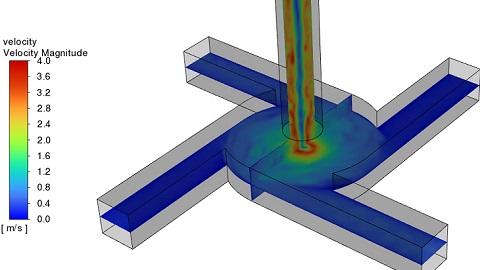

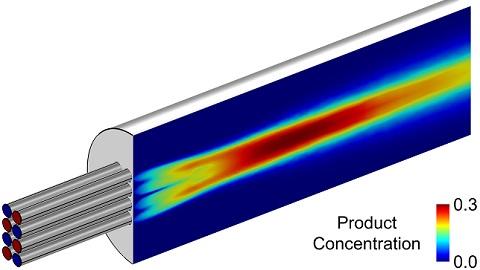

An example of turbulent mixing is shown in the animation below of flash nanoprecipitation (FNP) in a continuous multi-inlet vortex mixer. FNP is an efficient approach for high volume manufacturing of nanoparticles, such as the lipid nanoparticles found in mRNA vaccines, that relies on the rapid mixing of streams containing the nanoparticle components. Veryst was able to predict micromixing rates in a multi-inlet vortex mixer for lipid nanoparticle production using high-fidelity computational fluid dynamics (CFD). Simulations such as these can help predict the minimum flow rate required to produce the desired nanoparticle size distributions while avoiding potentially damaging flow shear stresses.