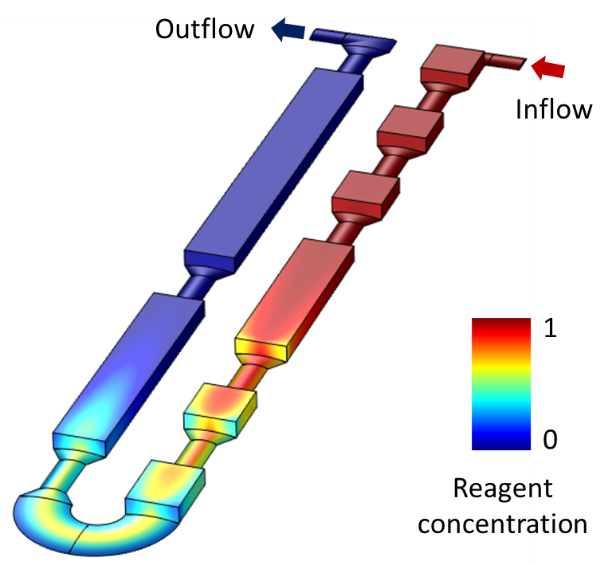

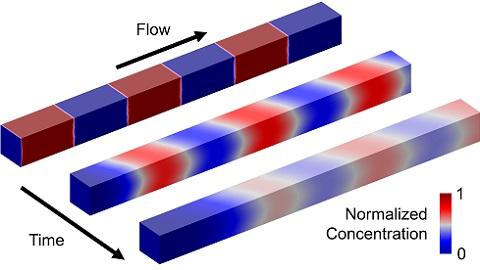

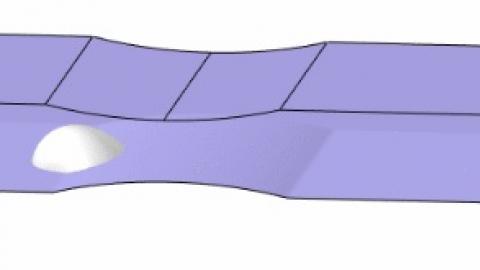

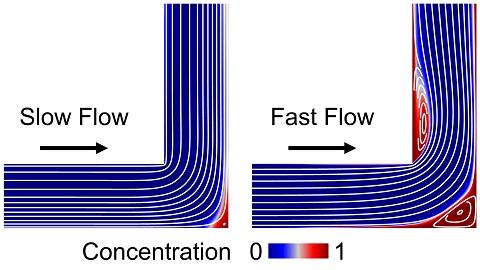

Veryst offers a comprehensive approach to solving problems in microfluidic device development. We employ an array of modeling tools, such as scaling arguments, analytical formulas, computational simulations, and laboratory testing to inform the design and integration of common components such as micropumps, manifolds, and channel networks, and to model processes such as shear stresses, transport of nutrients and waste, chemical reactions, heat transfer, and surface tension and wetting effects. For example, we have used computational fluid dynamics (CFD) tools to model oxygen transport and uptake by cells within an organ-on-a-chip microfluidic device, and have validated our predictions with our clients’ laboratory data. We have used CFD tools to optimize 3D channel networks and validated designs with 3D printing.

Our clients use our analysis and recommendations to develop new products and to improve the performance of existing products, which in some cases resulted in new intellectual property.

Expertise

- Fluid-structure interaction

- Heat and mass transfer

- Multiphase and particulate flow

- Flow in porous media

- Surface tension and wetting

- Acoustics

- Viscous and creeping flow

Applications

- Medical devices

- Biotechnology

- Pharmaceuticals

- Industrial processes

- Consumer products

- Micro devices

- Tissue engineering and regenerative medicine

- Diagnostic devices

- Digital microfluidics, emulsions

- Electronic cooling, thermal management

- Drug discovery and screening

Veryst Capabilities

- Analysis, modeling, and simulation of flow cells with surface reactions

- Lab-on-chip microdevices

- Bioinspired cooling

- Micro heat exchangers

- Marangoni and curvature pressure driven flows

- Structural-acoustic vibrations

- Droplet and bubble flows

- Electromagnetic heating

- Thermal-fluid coupling

- Conjugate heat transfer

- Particle transport and sorting

- Inertial microfluidics

- Organ-on-a-chip microdevices

- Colloidal flows

- Microchannel networks

- Phase change

- Microchannel mixing

- Multiphase flow in fibrous materials

- Wicking

- Lubrication

- Electrokinetic flows