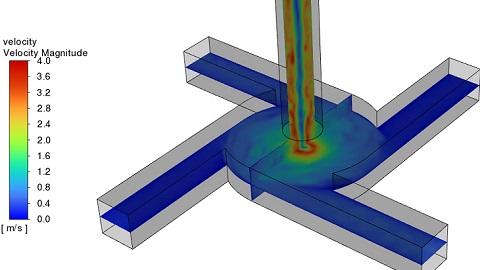

Veryst employs advanced computational fluid dynamics (CFD) tools and analytical models to understand and visualize complex flow behavior. We use our grounded knowledge of computational methods, fluid mechanics, and physics to provide practical design recommendations. Clients use our analyses to perform proof of concept investigations, understand product and process performance, and develop improvements, which has resulted in new intellectual property. We stress the importance of engineering fundamentals as well as testing and validation for all of our modeling efforts, due to the complexity and nonlinear nature of many of the applications we encounter.

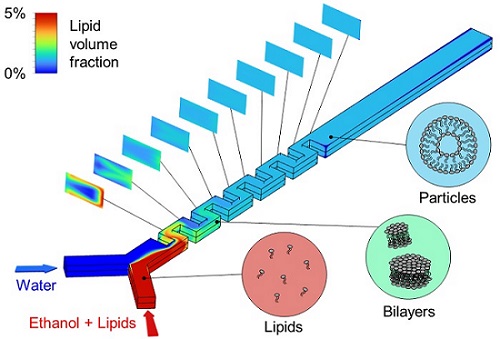

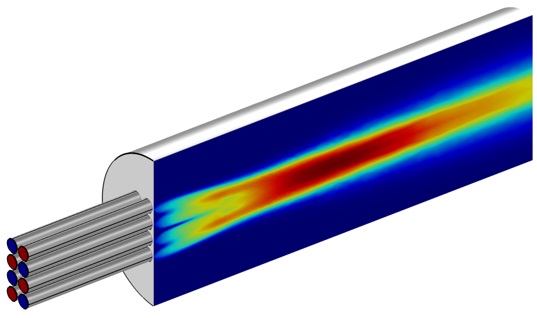

Our engineers’ experience includes using CFD tools to understand lipid nanoparticle self-assembly for mRNA vaccine production, biofluid dynamics problems, microscale flow and transport in microfluidic devices, flows of complex fluids like slurries or suspensions, and turbulent flows to predict mixing and heat transfer. Our fluid flow analyses often involve other physics such as heat and species transport, chemical reactions and combustion, fluid-structure interaction, surface tension and wetting, and particle or cell motion.

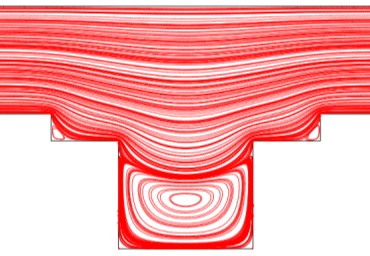

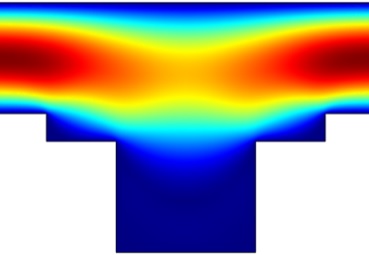

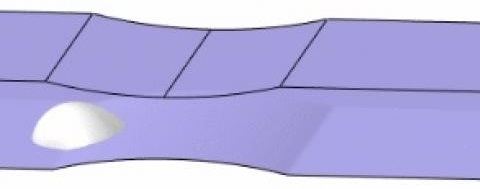

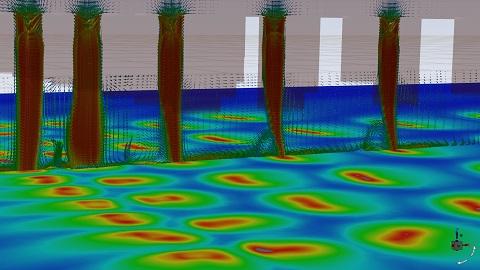

Streamlines and velocity magnitude of flow over grooves in a microchannel.

Fluid Mechanics Expertise

We work extensively in solving fluid mechanics problems, including laminar and turbulent flows, single and multiphase systems, and interaction with other physics.

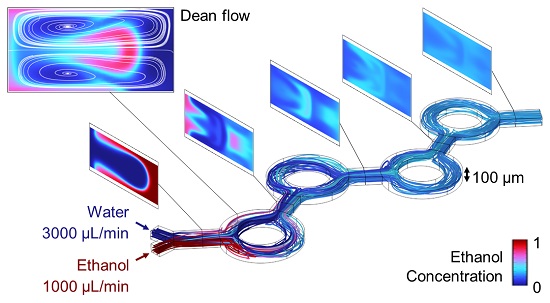

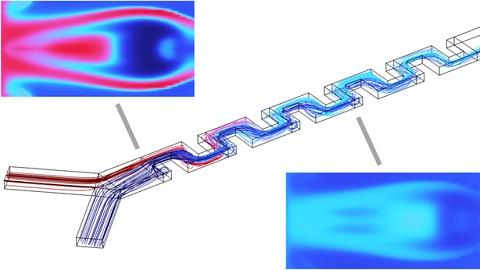

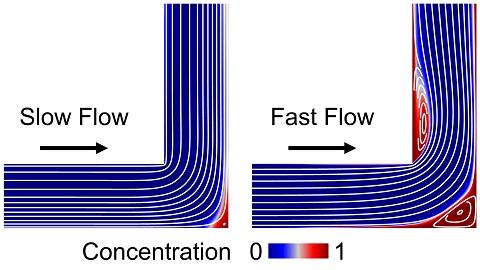

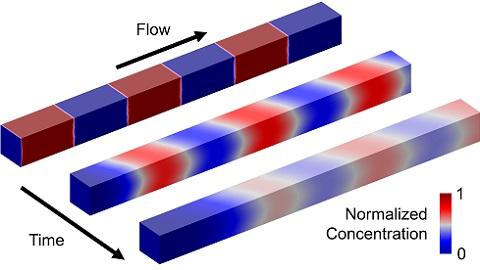

Mixing and Multicomponent Flows

A fundamental aspect of mixing is the stretching and folding of the interface between initially separated substances. This occurs in many forms and systems: agitated versus static mixers, laminar versus turbulent flows, lab versus production scale, etc. It also occurs in systems where mixing is weakly coupled with the flow (passive mixing) or tightly coupled with the flow (mixing of variable density substances, flows with chemical reactions, multiple phases, etc.).

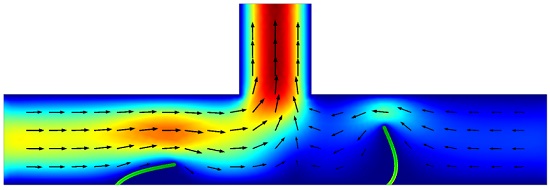

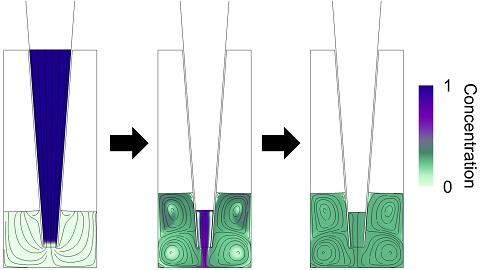

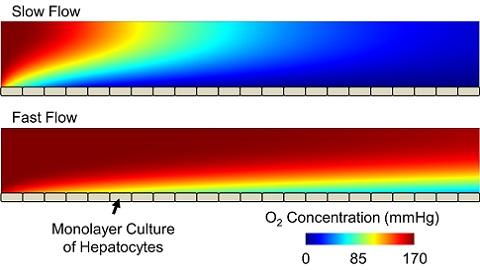

Microfluidics

Microfluidics is the science and engineering of devices and processes involving flow through channels and chambers whose smallest dimension is less than 1 mm. Examples include tools to model oxygen transport and uptake by cells within an organ-on-a-chip microfluidic device, chemical carryover and concentration gradients in a microchannel, chaotic microfluidic mixing, and lipid nanoparticle self-assembly for mRNA vaccine production. Read more about microfluidics.

Capillary Flows, Surface Tension and Wetting

Veryst has considerable expertise in surface tension and wetting and capillary flow phenomena including wicking, bubbles (nucleation and mitigation), droplets (generation, adhesion, flow), cavitation, water repellency, patterned wetting, electrowetting, electrokinetic flows, contact angle hysteresis, and leakage/seepage through valves and seals.

Multiphase Flow

Multiphase systems include two or more materials (gas, liquid, or solid) flowing and interacting with each other simultaneously. Examples of such systems include bubbles flowing through microchannels, the precipitation and self-assembly of lipid nanoparticles for mRNA vaccines, exhaled droplet plumes, sprays, nebulization, reagent dry-down and evaporation, and aqueous microdroplets transported in an immiscible oil carrier. The interaction of the various phases can be complex and requires expert knowledge of the appropriate numerical techniques to capture that complex behavior in a simulation.

Reacting Flows

Chemically reacting flows, like those found in bioreactors, engines, or fires, exhibit strong coupling between heat, mass, and momentum transport. For applications involving turbulent flows, modeling the turbulence-chemistry interaction with appropriate fidelity is critical to obtaining useful insights into highly nonlinear processes. For example, we’ve worked on the scale-up of bioreactors, thermal management of combustor liners, and flame propagation around obstacles within an enclosure.

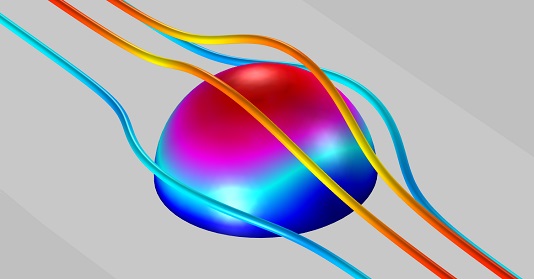

Fluid-Structure Interaction

Fluid-structure interaction (FSI) refers to analyses involving coupled fluid flow and solid deformation. Depending upon the problem, the interaction may be along a shared boundary or it may be internal to the structure, as in the case of poroelasticity. In addition to the solid and fluid deformation, FSI requires handling a moving mesh. Read more about fluid-structure interaction.

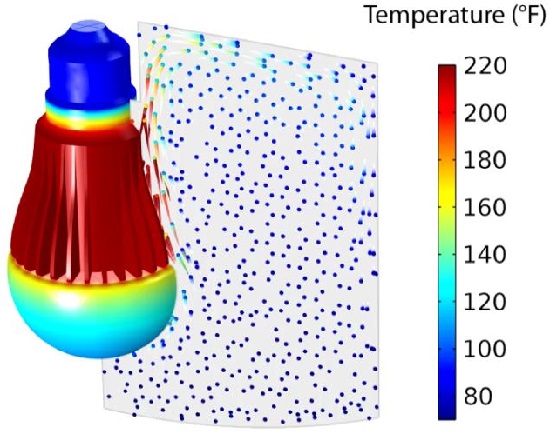

Thermal CFD and Conjugate Heat Transfer

Modeling of many thermal technologies requires coupling fluid-flow with heat transfer, often including conduction in the adjacent solids. The coupled processes can be highly complex, particularly if the fluid flow includes turbulence or if the heat transfer involves processes such as radiation, boiling, evaporation, or mixed fluids with varying thermal properties. Read more about thermal CFD.

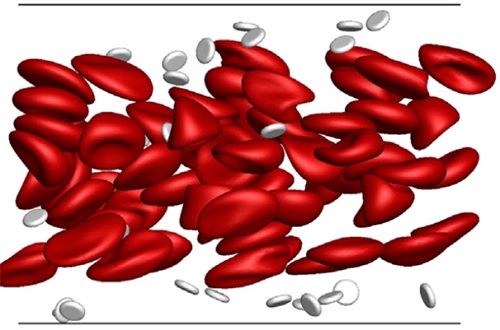

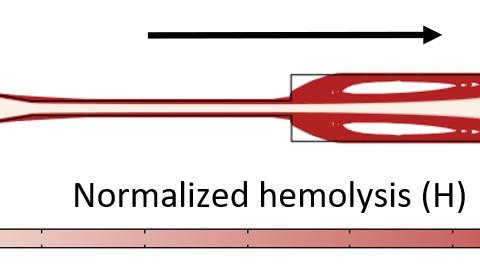

Complex Fluids and Rheology

Modeling processes involving complex fluids such as blood, particulate suspensions, and polymeric liquids requires sophisticated models and numerical techniques to capture their complex behavior. Even in small-scale, non-inertial flows, such fluids exhibit a nonlinear stress response due to their micro-constitutive elements that impacts their dynamics and stability. Example problems include blood flow and health, clogging of formulated products, granular abrasives, and binders in energy storage devices.